Low pressure gas-liquid driven reamer

Key words:

Classification:

- Product Description

- Instructions for use

- Application Case

- Product Parameters

-

- Commodity name: Low pressure gas-liquid driven reamer

- Commodity ID: 1248589701933846528

In recent years, a variety of technologies have been developed and applied in coal seam permeability increasing mining technology, and many schemes have been discussed and used in many areas for coal seam gas extraction technology in bottom drainage tunnel. At present, the most widely used hole bottom hole drilling technology is an effective solution to increase the concentration of gas extraction. Using high-pressure water to punch holes can quickly and effectively achieve the purpose of hole bottom hole making, the water jet is used to break and cut the coal seam in the relative position, which increases the local space and improves the gas extraction rate. However, in case of soft coal seam with excessive gas content and loose coal quality, the coal powder is washed with high-pressure water, which is easy to cause the foaming loss of coal powder and the accumulation of coal cinder seriously causes pressure drilling.

-

1. system compositionThis system consists of crawler type full hydraulic tunnel drilling rig ZDY4200L for coal mine, double-wall gas-liquid channel drill pipe Φ73mm * 1m, low pressure gas-liquid driven reamer Φ400-500mm, double-channel gas-liquid water tail, diamond PDC bit Φ113mm, special gas-liquid control box, etc.2. Technical SchemeLow-pressure gas-liquid drive reamer, the so-called low-pressure, that is, the use of not more than 0.63Mpa pressure air or less than 5Mpa liquid as power output, to achieve mechanical hole reaming at the bottom of the hole, the use of low-pressure gas-liquid to provide power, drive set at the bottom of the reamer to push.The multi-stage force doubling device is a multi-fold incremental propulsion structure, and is provided with a propulsion piston larger than 1 stage, relying on the multi-stage synchronous motion of the propulsion piston to achieve the purpose of thrust multiplication.The bottom of the multi-stage force doubling device is provided with a gas-liquid inlet. When low-pressure compressed air or liquid flows through the multi-stage force doubling device, it generates driving thrust for the first-stage propulsion piston. At the same time, it flows through the second-stage propulsion piston and other multi-stage propulsion pistons. The piston rod extending from the thrust piston is pushed out to connect with the knife body piston to advance the knife body piston to control the opening and closing of the knife wing, the alloy for coal body cutting is evenly arranged on the periphery of both sides of the blade.The end face of the piston shaft is connected with the built-in piston rod of the multi-stage force doubling device and provides axial thrust. When the thrust reaches a certain value, the piston shaft is pushed to perform axial movement to drive the opening and closing movement of the blade.3. Implementation SchemeThe front end of the low pressure gas-liquid drive reamer is connected with the bit, and the rear end is connected with the double-wall gas-liquid channel drill pipe. The double-wall gas-liquid channel drill pipe is connected with the double-channel gas-liquid tail and is rotated by the drilling rig. When drilling, the pressure air or cooling water from the outside enters the drill pipe ring cavity through the quick connector at the side end of the double-channel gas-liquid tail to-liquid tail to cool down.When drilling to a certain position to carry out reaming operation, the low-pressure air or liquid connected to the rear end of the double-channel gas-liquid water tail uses the low-pressure air or liquid provided inside the reamer as power to push the multi-stage double force device to move so as to drive the piston shaft inside the cutter body to move, and the cutter wing is pushed to open and break the coal body by the engagement of the rack of the piston shaft and the gear, cut off the input source after finishing the job,Reverse push reset is performed by an internally provided reset device.(2) Technical operation essentialsThe two-channel gas-liquid tail is equipped with a special regulating gas-liquid control device. When hole making is carried out, first determine whether the pressure indicated by the pressure gauge on the regulating gas-liquid control device reaches the applicable pressure, and then open the access control ball valve. At this time, the drilling rig should be in a rotating state, so that the blade is in a rotating force state when it is opened, so as not to cause sticking accident. Then start hole making in the hole making, open the pressure relief ball valve to release the pressure in the channel pipeline and close the blade in the hole.

-

-

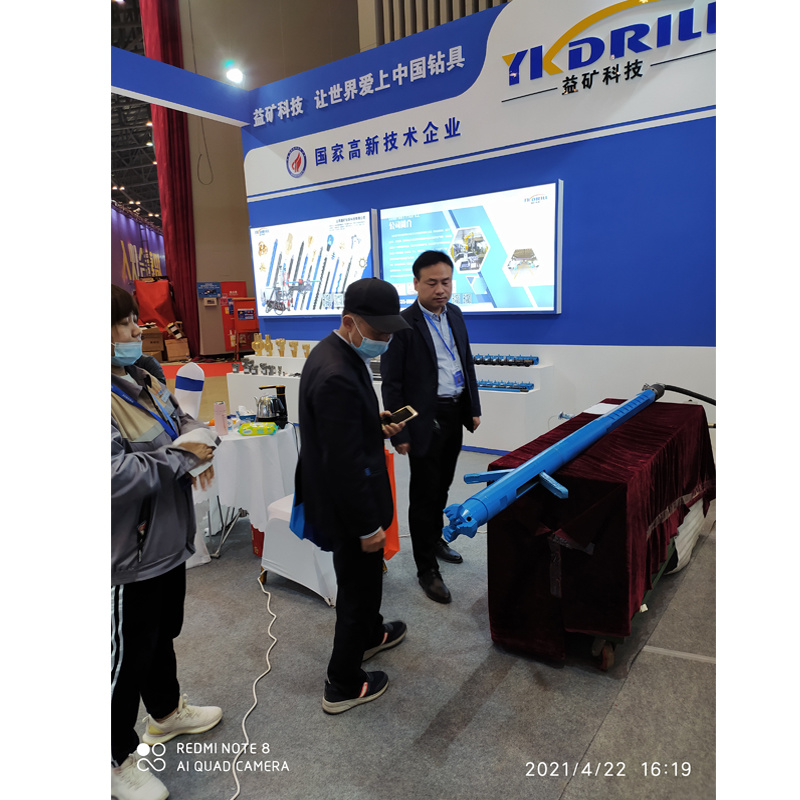

★ COMPANY PROFILE ★

Shandong Yikuang Drilling Technology Co.,Ltd. Located in Linqing City, a famous city of the ancient Beijing-Hangzhou Canal and an important industrial town in Shandong Province, it is located 500 meters south to the west at the intersection of 323 Provincial Highway and 247 Provincial Highway of Youth Sub-district Office. The company has a registered capital of 50 million yuan and the factory covers an area of 100000 ㎡. It is a high-tech enterprise integrating technology development and equipment manufacturing, sales and technical services in the fields of geological drilling, coal mining, engineering anchoring, gas and dust disaster control.

Since its establishment, the company has been committed to the development and application of drilling, mining, anchoring and equipment in coal mines, mines, construction and water conservancy projects, railways, highways, tunnels and bridges. In 2018, "Liaocheng industrial and mining safety protection drilling tool engineering technology research center" was settled here, and was successively rated as "national high-tech enterprise", "provincial specialized and special new enterprise", "science and technology small and medium-sized enterprise" and "Shandong gazelle enterprise" Liaocheng "one enterprise, one technology" R & D center. The company has established long-term strategic cooperative relations with many scientific research institutions and equipment enterprises. The strength of the company, there is a professor, associate professor, doctor, master and other composed of more than 40 people of high-quality scientific and technological personnel. Relying on the talent and technical advantages of many mining universities and strategic cooperation units, and aiming at the needs of coal, mining, construction engineering and other industries, it has developed and produced a number of drilling products and equipment with independent intellectual property rights.

★ QUALIFICATION CERTIFICATION ★

★ APPLICATION FIELD ★

★ CONTACT US ★

Related classification