R32-Round32-R32 Quick-connect Drill Rod

Key words:

Classification:

- Product Description

- Instructions for use

- Application Case

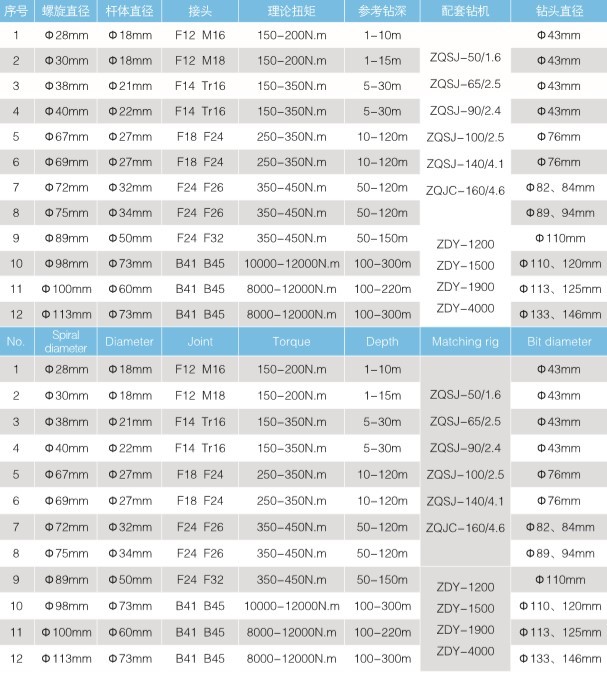

- Product Parameters

-

- Commodity name: R32-Round32-R32 Quick-connect Drill Rod

- Commodity ID: R32-Round32-R32快接钎杆

- 上架时间:: 2016-12-16 15:53

Product introduction: trolley quick connection drilling tools mainly include: R25, R28, R32. the threads at both ends are generally one external thread and one internal thread to realize the quick and direct connection of drill pipe with drill bit, drill pipe and drill tail. Threaded connection of the drill bit, drill rod, drill sleeve and drill tail, products and world-renowned brands of rock drilling rigs can be used; products are selected from the world's best quality steel for drilling tools, all using a number of empty lathe processing, vacuum furnace for heat treatment, product performance reached the international advanced level, the products sell well at home and abroad. The company can also be customized according to customer requirements non-standard drill products. Scope of application: mines, quarries, highways and other work

Product introduction:

The trolley quick connection drilling tools mainly include: R25, R28, R32, and the threads at both ends are generally one external thread and one internal thread to realize the quick and direct connection between the drill pipe and the drill bit, drill pipe and drill tail. Threaded connection of the drill bit, drill rod, drill sleeve and drill tail, products and world-renowned brands of rock drilling rigs can be used; products are selected from the world's best quality steel for drilling tools, all using a number of empty lathe processing, vacuum furnace for heat treatment, product performance reached the international advanced level, the products sell well at home and abroad. The company can also be customized according to customer requirements non-standard drill products.

Scope of application: mines, quarries, highways and other projects drilling blasting holes, guardrail holes, mountain reinforcement, anchoring and other engineering holes, geothermal air conditioning holes, water well holes and other fields.

Maintenance instructions:

1, the drill rod needs regular maintenance to determine the maintenance cycle, regular anti-rust and dust treatment.

2. The use of drill rod shall be within the rated drilling distance of the drilling rig, and the matching drill rod shall be adopted according to the technical parameters of the drilling distance.

3. The drill rod is made of friction welding of special geological drilling pipes for mining geology and their matching joints, so it has good follow-up and high tensile strength, and can be adapted to drilling and gas discharge in regular. When working in hard rock, coal seam or other special environment, the drilling depth shall be determined according to the physical properties and parameters of the actual material of the drill pipe.

4. When the drill rod and the drill bit are used together, the drill bit should be larger than the diameter of the drill pipe under normal circumstances, and the condition of the drill and the drill pipe should be paid attention to at all times during the drilling process. In case of sticking, sudden death, etc., stop drilling immediately or drill slowly after returning to ensure that the drill pipe is not bent and flat.

5. When the drill rod is ventilated or ventilated, the drill rod shall be tightly connected during drilling. When the geological drill pipe has seals, such as O-ring seals, attention should be paid to the use of the seals, and the seals should be replaced in time when damage, corrosion and other phenomena occur. After the drilling is completed, do maintenance and cleaning work on the seal.

6. When drilling, the drill rod should be tightened manually to ensure close fit (thread type). It is not allowed to drill directly with the drill to prevent damage to the drill rod.

7. If the bending degree of the drill rod after use exceeds the standard requirements or the thread damage causes the normal operation to be impossible, it shall be scrapped or returned to the factory for repair in time.

8, according to the standard requirements, should ensure the drilling depth of the drill pipe composite geological drilling related requirements to prevent the drill pipe due to the drilling depth to reach the limit of the use of the drill pipe, the occurrence of falling off phenomenon.

9. When working in acid and alkali areas, attention should be paid to the corrosion of drill pipes. When drilling is completed, clean the surface of the rod body with clean water in time to remove the corrosion layer.

10. The drill rod shall be stored in a dry place, the bottom shall be supported at multiple points, and the drill rod shall be regularly maintained during long-term storage.

11. The drill rod shall not be used as a supporting platform for heavy tail stacking, and the drill rod shall not be randomly placed under gravel, coal pile or scattered pile.

12, drill rod maintenance after rust removal/dust cleaning should buckle protective cap or packing seal to ensure that the drill pipe is often new.

-

Drill rods are used in conjunction with hydraulic rock drills (e. g. Atlas, Guhe, Tomlock). The product has the characteristics of stable quality and high cost performance. It is a substitute for foreign drill pipe.

Rock drilling rig drill pipe is widely used in mining, tunnel drilling, underground plant excavation. The products are mainly used for export.

-

The rock drilling platform products produced by our company are widely used in various regions at home and abroad. The main domestic use areas are: China Coal Group, Longmei Group, Shen Coal Group, Fengfeng Coal Industry, Kailuan Coal Industry, Lu'an Coal Industry, Yangmei Group, Jinmei Group, Xishan Coal Power, Fenxi Coal Industry, Datun Coal Industry, Xinji Energy, etc. The main use areas of foreign regions are Russia, Australia, Southeast Asia and Northern Europe.

-

★ COMPANY PROFILE ★

Shandong Yikuang Drilling Technology Co.,Ltd. Located in Linqing City, a famous city of the ancient Beijing-Hangzhou Canal and an important industrial town in Shandong Province, it is located 500 meters south to the west at the intersection of 323 Provincial Highway and 247 Provincial Highway of Youth Sub-district Office. The company has a registered capital of 50 million yuan and the factory covers an area of 100000 ㎡. It is a high-tech enterprise integrating technology development and equipment manufacturing, sales and technical services in the fields of geological drilling, coal mining, engineering anchoring, gas and dust disaster control.

Since its establishment, the company has been committed to the development and application of drilling, mining, anchoring and equipment in coal mines, mines, construction and water conservancy projects, railways, highways, tunnels and bridges. In 2018, "Liaocheng industrial and mining safety protection drilling tool engineering technology research center" was settled here, and was successively rated as "national high-tech enterprise", "provincial specialized and special new enterprise", "science and technology small and medium-sized enterprise" and "Shandong gazelle enterprise" Liaocheng "one enterprise, one technology" R & D center. The company has established long-term strategic cooperative relations with many scientific research institutions and equipment enterprises. The strength of the company, there is a professor, associate professor, doctor, master and other composed of more than 40 people of high-quality scientific and technological personnel. Relying on the talent and technical advantages of many mining universities and strategic cooperation units, and aiming at the needs of coal, mining, construction engineering and other industries, it has developed and produced a number of drilling products and equipment with independent intellectual property rights.

★ QUALIFICATION CERTIFICATION ★

★ APPLICATION FIELD ★

★ CONTACT US ★

Related classification