Φ51-R32 Rock Drill Bit-Yikuang Technology

Key words:

Classification:

- Product Description

- Instructions for use

- Application Case

- Product Parameters

-

- Commodity name: Φ51-R32 Rock Drill Bit-Yikuang Technology

- Commodity ID: FTZ-135

- 上架时间:: 2016-10-18 16:53

- 直径:: 51

- 长度:: 80

- 螺纹形式:: R-type thread

- 生产工艺:: Precision forged high-quality alloy steel

- 适用范围:: Used for limestone, marble and iron ore, gold ore drilling engineering

-

Wind drill bit · Use method and matters needing attention1. The taper of the drill bit and the drill rod shall be effectively matched, and the matching length shall be ≥ 25mm. Please select the appropriate drill rod according to this principle.2. The unloader shall be used to unload the drill, and hammers are strictly prohibited.3. When grinding the drill bit, the chip drill bit must be controlled in use. When the drill bit is drilled slowly and the obtuse angle width Δ at both ends of the drill bit is ≥ 2.5mm, the drill bit shall be ground in time. When grinding, 46-60 silicon carbide grinding wheel shall be used, and the line speed shall not be less than 18 m/s.Wind bit maintenance instructions1. Ensure a good fit with the tapered drill rod (the taper is consistent, the depth of the drill rod inserted into the drill hole must be greater than 25mm, and the drill rod head should not be full of the drill hole bottom), otherwise the drill bit is easy to lose; Note: It is better to use the same manufacturer as the tapered drill rod to ensure the same taper and good cooperation.2. When drilling holes, the rock drill shall reduce the air volume to reduce the damage to the drill bit caused by high stress in the local part of the hard alloy sheet. When the drill bit is completely drilled into the rock, the normal air volume shall be used;3, when the drill bit edge platform width ≥ 3mm, should be timely replacement or grinding, so as not to reduce the drilling speed, resulting in drill bit fragments, lobes, reduce the service life;4. When using the drill bit, if you encounter foreign matters such as steel bars, you should adjust the drilling position to prevent the drill bit from being damaged;5. When rock drilling is prone to jamming, the in-line drill bit should be replaced with cross drill bit or ball tooth drill bit;6. For rocks that cause serious wear of straight-shaped drill bits, slow drilling footage and serious debris, consideration should be given to replacing other alloy brands of drill bits or using cross-shaped drill bits and ball tooth drill bits, and our company should be notified in writing in time so as to deal with them in time.

-

-

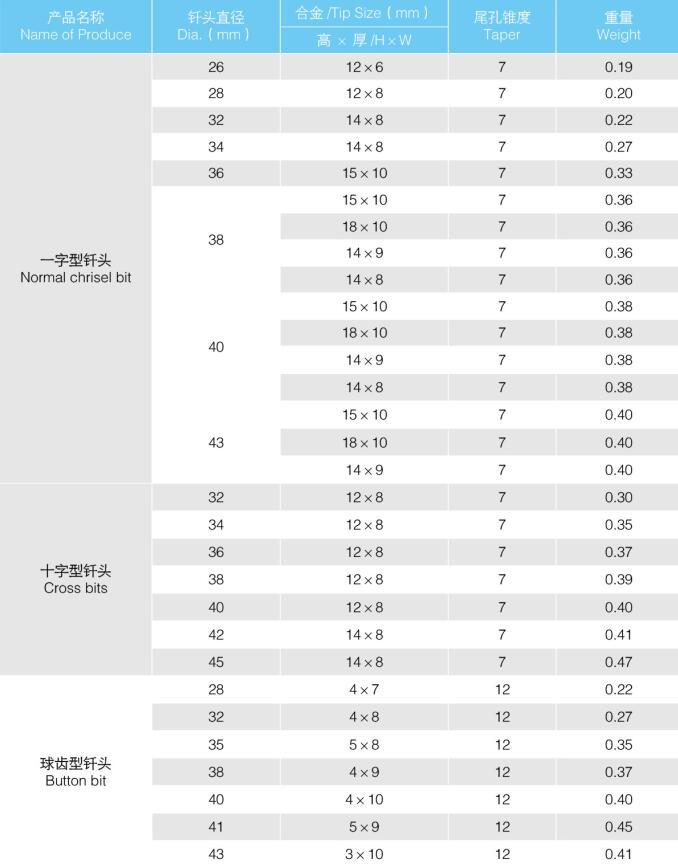

column tooth bitAlso known as button bit, combined with hydraulic rock drilling rig, is the best supporting modern rock drilling technology.

The most commonly used type of column tooth drill is [32 column tooth drill, 40 column tooth drill].

Taper connection drill tool post tooth drill bit 7 °, 11 °, 12 °"

The advantages of column tooth drill bit: long service life, accurate positioning, coarse rock cuttings, low dust, durability, no need for grinding, etc., compared with traditional sheet drill bit, fast drilling speed, long passivation service life of button tooth drill bit, its non-grinding life is about 5-6 times of the grinding life of the same diameter blade drill bit, which is conducive to saving auxiliary working hours, reducing labor and physical strength of workers and speeding up the project speed.

The hardest part of the column tooth drill is the upper column head, which is made of wear-resistant alloy, and the lower shank barrel is cast steel. The following threads have inner threads and those without threads. When ordering mainly, the type of thread should be determined according to the thread of the customer's drill pipe.

Column tooth bits are mainly divided into the following categories:

1. DTH column tooth bit

The down-the-hole column tooth drill bit is a kind of drill bit which is used in combination with the down-the-hole impactor. It is widely used in open-pit mining, quarry, hydropower project, well drilling and excavation side column support, etc. It is divided into: low-pressure down-the-hole column tooth bit, medium and high wind pressure down-the-hole column tooth bit. The down-the-hole column tooth bit is used in conjunction with the down-the-hole impactor, which has the characteristics of straight drilling, fast speed and deep drilling.

2. Taper connection column tooth bit

The taper connection column tooth bit is mainly used with the pneumatic rock drill and taper rod supporting the use of a bit, through the taper and drill rod connection, drilling operations, mainly used in the secondary crushing of the mine, bolt support, roadway excavation and other fields.

3. Threaded connection column tooth bit

The threaded connection column tooth is mainly a kind of drill bit used in conjunction with hydraulic rock drill (or pneumatic rock drill) and hydraulic drill rod (pneumatic drill rod). Drilling operation is carried out by matching different forms of threads with drill rods. The drill bit is directly connected from ¢ 32-¢ 203mm.

★ COMPANY PROFILE ★

Shandong Yikuang Drilling Technology Co.,Ltd. Located in Linqing City, a famous city of the ancient Beijing-Hangzhou Canal and an important industrial town in Shandong Province, it is located 500 meters south to the west at the intersection of 323 Provincial Highway and 247 Provincial Highway of Youth Sub-district Office. The company has a registered capital of 50 million yuan and the factory covers an area of 100000 ㎡. It is a high-tech enterprise integrating technology development and equipment manufacturing, sales and technical services in the fields of geological drilling, coal mining, engineering anchoring, gas and dust disaster control.

Since its establishment, the company has been committed to the development and application of drilling, mining, anchoring and equipment in coal mines, mines, construction and water conservancy projects, railways, highways, tunnels and bridges. In 2018, "Liaocheng industrial and mining safety protection drilling tool engineering technology research center" was settled here, and was successively rated as "national high-tech enterprise", "provincial specialized and special new enterprise", "science and technology small and medium-sized enterprise" and "Shandong gazelle enterprise" Liaocheng "one enterprise, one technology" R & D center. The company has established long-term strategic cooperative relations with many scientific research institutions and equipment enterprises. The strength of the company, there is a professor, associate professor, doctor, master and other composed of more than 40 people of high-quality scientific and technological personnel. Relying on the talent and technical advantages of many mining universities and strategic cooperation units, and aiming at the needs of coal, mining, construction engineering and other industries, it has developed and produced a number of drilling products and equipment with independent intellectual property rights.

★ QUALIFICATION CERTIFICATION ★

★ APPLICATION FIELD ★

★ CONTACT US ★

Related classification