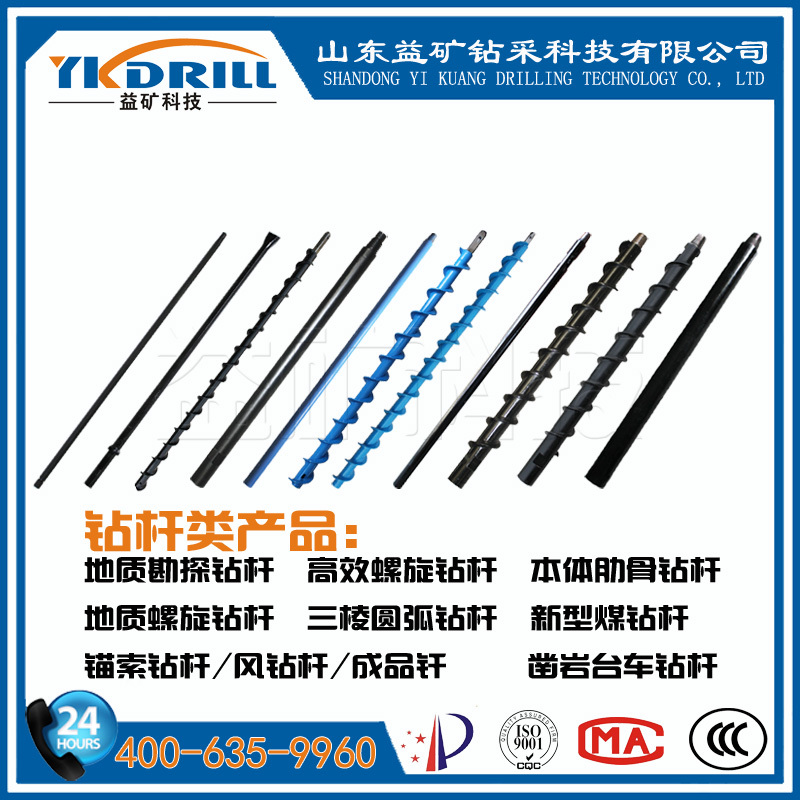

Φ133-63.5-5.08-1.5 m (cone, buckle, male, milled and flattened) geological spiral drill pipe

Key words:

Classification:

- Product Description

- Instructions for use

- Application Case

- Product Parameters

-

- Commodity name: Φ133-63.5-5.08-1.5 m (cone, buckle, male, milled and flattened) geological spiral drill pipe

- Commodity ID: Φ133-63.5-5.08-1.5米

- 上架时间:: 2016-12-13 16:28

Material: The geological spiral drill pipe body is made of high-quality alloy steel pipe for geology, and the drill pipe joint is made of high-quality alloy structural steel. Features: 1. The drill pipe has the characteristics of high bending strength and firm welding; 2. The characteristics of high production efficiency and stable quality; 3. The ultra-low spiral spiral blade design makes the geological spiral drill pipe have the characteristics of large torque, fast slag discharge speed, good drilling and forming, and not easy to jam. Application: It is especially suitable for deep-hole drilling of soft coal seams and coal-like rocks with poor slagging effect.

Material: The geological spiral drill pipe body is made of high-quality alloy steel pipe for geology, and the drill pipe joint is made of high-quality alloy structural steel.

Features:

1. The drill pipe has the characteristics of high bending strength and firm welding;

2. The characteristics of high production efficiency and stable quality;

3. The ultra-low spiral spiral blade design makes the geological spiral drill pipe have the characteristics of large torque, fast slag discharge speed, good drilling and forming, and not easy to jam.

Application: It is especially suitable for deep-hole drilling of soft coal seams and coal-like rocks with poor slagging effect.

-

Maintenance11. Drill pipe shall be regularly maintained to determine the maintenance period, and be regularly treated for rust and dust prevention.

2The use of drill pipe shall be within the rated drilling distance of the drilling rig, and the matching drill pipe shall be used according to the technical parameters of the drilling distance.

3The geological drill pipe is made of special geological drilling pipe for mining geology and its matching joint friction welding, so it has good follow-up and high tensile strength, and can be adapted to regular drilling and gas discharge. When working in hard rock, coal seam or other special environment, the drilling depth shall be determined according to the physical properties and parameters of the actual material of the drill pipe.4When the drill pipe and the drill bit are used together, the drill bit should be larger than the diameter of the drill pipe under normal circumstances, and the condition of the drill and the drill pipe should be paid attention to at all times during the drilling process. In case of sticking, sudden death, etc., stop drilling immediately or drill slowly after returning to ensure that the drill pipe is not bent and flat.

5When the drill pipe is ventilated or ventilated, the drill pipe shall be tightly connected during drilling. When the drill pipe has seals, as shown inOThe seal ring should pay attention to the use of the seal, and replace the seal in time when it is damaged or corroded. After the drilling is completed, do maintenance and cleaning work on the seal.

6The drill pipe shall be manually and gently tightened during drilling to ensure tight fit (thread type). It is not possible to directly drill the drill pipe to prevent damage to the drill pipe.

7If the bending degree of the drill pipe after use exceeds the standard requirements or the normal operation cannot be performed due to thread damage, the drill pipe shall be scrapped or returned to the factory for repair in time.

8According to the standard requirements, the drilling depth of the drill pipe shall be guaranteed to prevent the drill pipe from falling off due to the drilling depth reaching the service limit of the drill pipe.

9When working in the acid-base area, attention should be paid to the corrosion effect on the drill pipe. When drilling is completed, clean the surface of the rod body with clean water in time to remove the corrosion layer.

104. The drill pipe shall be stored in a dry place, the bottom shall be supported at multiple points, and the drill pipe shall be regularly maintained during long-term storage.

113. The drill pipe shall not be used as a supporting platform for heavy tail stacking, and shall not be randomly placed under gravel and coal pile or randomly stacked.

12Rust removal/After dust cleaning, the protective cap shall be fastened or packed and sealed to ensure that the drill pipe is normally new.

-

Parameters

Serial Number Diameter Length Thread form Production process Connection form with drilling machine Steel Grade Material 1 F50-42 500 ~1500 taper thread friction welding Clamping outer circle DZ50 45Mn2 2 F63.5-42 500~1500 taper thread friction welding Clamping outer circle DZ50 45Mn2 3 F63.5-50 500~1500 taper thread friction welding Clamping outer circle DZ50 45Mn2 4 F73-50 500~1500 taper thread friction welding Clamping outer circle DZ50 45Mn2 5 F73-63.5 500~1500 taper thread friction welding Clamping outer circle R780 36Mn2v 6 F90-63.5 500~1500 taper thread friction welding Equipped with active drill pipe R780 36Mn2v 7 F98-73 500~1500 hexagonal connection friction welding Equipped with active drill pipe R780 36Mn2v 8 F110-63.5 500~1500 taper thread friction welding Equipped with active drill pipe R780 36Mn2v 9 F130-63.5 500~1500 taper thread friction welding Equipped with active drill pipe R780 36Mn2v 10 F140-73 500~1500 taper thread friction welding Equipped with active drill pipe R780 36Mn2v

★ COMPANY PROFILE ★

Shandong Yikuang Drilling Technology Co.,Ltd. Located in Linqing City, a famous city of the ancient Beijing-Hangzhou Canal and an important industrial town in Shandong Province, it is located 500 meters south to the west at the intersection of 323 Provincial Highway and 247 Provincial Highway of Youth Sub-district Office. The company has a registered capital of 50 million yuan and the factory covers an area of 100000 ㎡. It is a high-tech enterprise integrating technology development and equipment manufacturing, sales and technical services in the fields of geological drilling, coal mining, engineering anchoring, gas and dust disaster control.

Since its establishment, the company has been committed to the development and application of drilling, mining, anchoring and equipment in coal mines, mines, construction and water conservancy projects, railways, highways, tunnels and bridges. In 2018, "Liaocheng industrial and mining safety protection drilling tool engineering technology research center" was settled here, and was successively rated as "national high-tech enterprise", "provincial specialized and special new enterprise", "science and technology small and medium-sized enterprise" and "Shandong gazelle enterprise" Liaocheng "one enterprise, one technology" R & D center. The company has established long-term strategic cooperative relations with many scientific research institutions and equipment enterprises. The strength of the company, there is a professor, associate professor, doctor, master and other composed of more than 40 people of high-quality scientific and technological personnel. Relying on the talent and technical advantages of many mining universities and strategic cooperation units, and aiming at the needs of coal, mining, construction engineering and other industries, it has developed and produced a number of drilling products and equipment with independent intellectual property rights.

★ QUALIFICATION CERTIFICATION ★

★ APPLICATION FIELD ★

★ CONTACT US ★

Related classification