Quadruple Efficacy of Special-shaped Multi-edge Groove Drill Pipe ---- Yikuang Technology

Release time:

2021-03-09

Author:

Source:

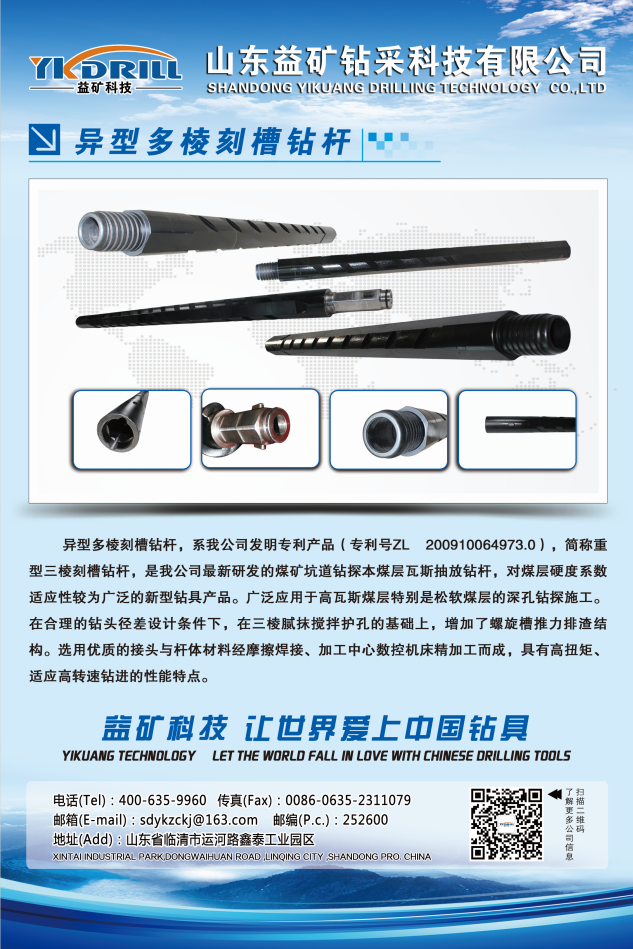

The four functions of the special-shaped multi-edge grooved drill pipe are as follows: 1. The patented structure of the protective hole is rotated in the loose drilling slag to cause the axial vortex flow along the rod body to form a slag discharge airflow, and the drilling slag is discharged through the slag discharge channel formed by the spiral groove. When the drill pipe is buried by the loose drilling slag or the drilling hole collapses, the drilling slag can be discharged through the slag discharge channel. 2, quenched and tempered nitrided drill pipe to join the heat treatment process to strengthen the overall force performance, so that it has a strong hardness and good plasticity and toughness, the joint by nitriding treatment to further strengthen the anti-grinding, anti-fatigue, anti-corrosion and anti-high temperature characteristics. 3. The multi-edge structure of the cooling function rod body can reduce the contact area between the drill pipe and the hole wall,

The four functions of the special-shaped multi-edge grooved drill pipe are as follows:

The four functions of the special-shaped multi-edge grooved drill pipe are as follows:

1. Pressure relief of protective hole

The patented structure rotates in the loose drilling slag to cause the axial vortex flow along the rod body to form a slag discharge air flow, which discharges the drilling slag through the slag discharge channel formed by the spiral groove, and when the drill rod is buried by the loose drilling slag or the borehole collapses, the drilling slag can be discharged through the slag discharge channel.

2. tempering and nitriding

The drill pipe is added to the heat treatment process to strengthen the overall force performance, so that it has strong hardness and good plasticity and toughness, and the joint is further strengthened by nitriding treatment to resist grinding, fatigue resistance, corrosion resistance and high temperature resistance.

3. Cooling function

The multi-edge structure of the rod body can reduce the contact area between the drill pipe and the hole wall. The rotation of the drill pipe forms a vortex airflow, which drives the cinder to flow in the spiral groove, which can take away the heat generated by the rotation friction of the drill pipe in time, and the drill pipe does not generate heat, thus providing guarantee for smooth drilling.

4. Directional righting

Using the influence of the axial force of the self-weight balance of the drill pipe and the rotating centrifugal force, the deflection of the drill tool is corrected, the bending of the drill hole is avoided, the alternating load generated during the rotation of the drill tool is suppressed, the wear of the drill bit is reduced, and the use loss of the drill tool is reduced.

Key words:

Next Page