Integrated Construction Scheme of Drilling and Pumping under Screen Pipe with Large Through Hole in Yiguang Science and Technology

Release time:

2021-06-03

Author:

Source:

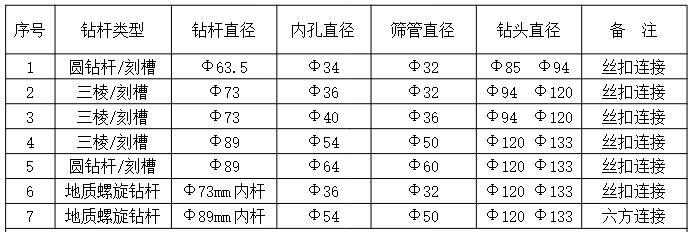

1. Product Background Using regular drilling technology to drill holes in high-gas soft outburst coal seams is easy to cause accidents such as hole collapse and holding, which not only increases the difficulty of drilling construction, but also causes blockage of drainage holes due to unstable collapse of the hole wall after drilling construction is completed, which affects the drainage effect. How to improve the gas drainage concentration and drainage volume of soft outburst has always been a major problem in coal mine gas control. The construction technology of lowering the screen pipe from the inner hole of the drill pipe after drilling can solve the problem of blockage of the drainage hole caused by the collapse of the drilling hole, thus improving the drainage effect. 2. matching of products: gas (methane) is the initial stage of accumulation of ancient plants into coal, cellulose and

4. construction scheme

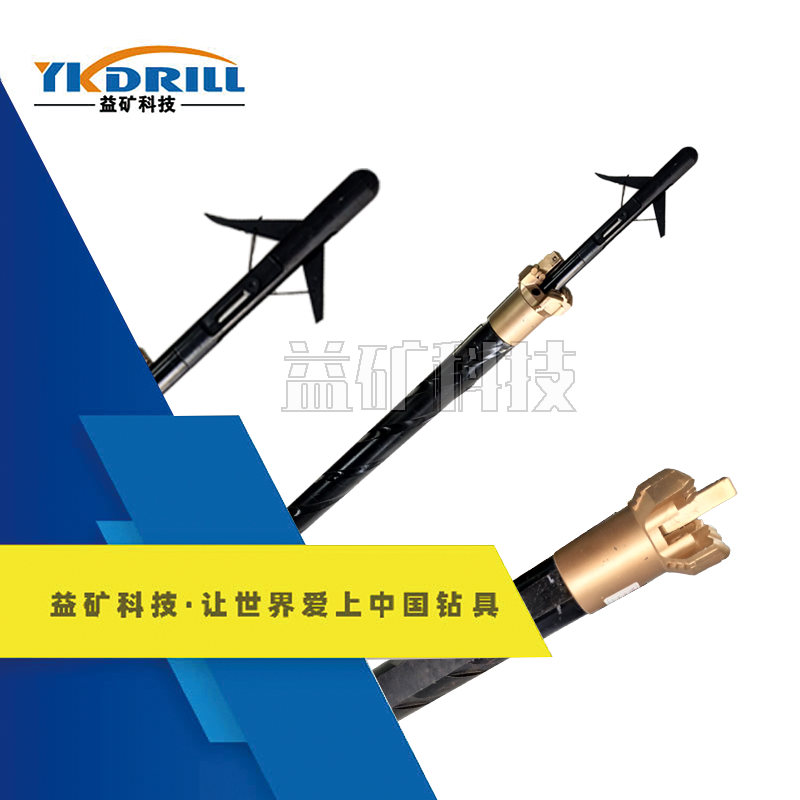

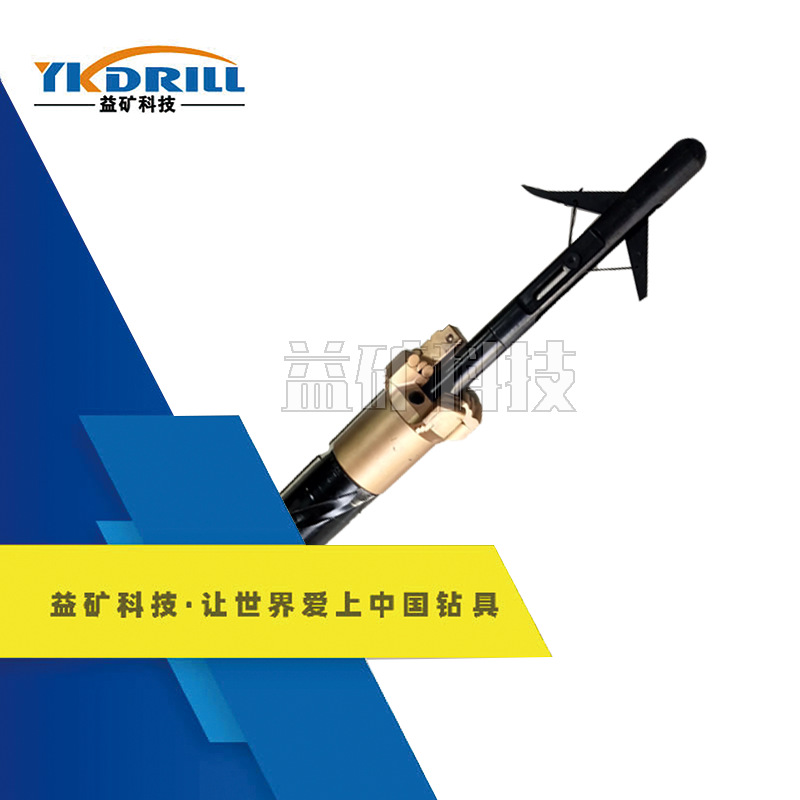

The hydraulic crawler provided by the mine is used, with our Φ89mm × 1m large hole grooved drill pipe and Φ120mm diamond PDC drill bit. The drilling diameter is Φ120mm, the drilling design depth is 200 m, the diameter of the screen tube is Φ60mm, and the drilling screen tube is simultaneously laid and drilled by air (water) cooling and dust reduction.

During the drilling operation, the pressure of the drilling rig shall be kept within 6Mpa. When the WOB increases, the advancing operation shall be stopped, the slag shall be discharged by rotation, the water supply ratio shall be reduced rapidly, or the drilling shall be withdrawn until the pressure of the drilling rig returns to the normal value. When drilling, Φ120 diamond PDC drill bit shall be used to drill holes first, then Φ89 large and large hole slotted drill pipes shall be connected in turn, the water tail connecting the drill pipe behind the power head of the drilling machine shall be removed after drilling to a fixed depth, then the suspension device shall be screwed onto a gas screen pipe, the suspension device shall be closed, then the Φ89mm × 1m large and large hole slotted drill pipes shall be inserted into the gas screen pipe in turn, after the drill pipe footage reaches the specified depth, slowly apply force to open the opening and closing blade at the top of the drill bit, then push the suspension device out of the drill bit completely to ensure that the suspension device is completely hung on the coal wall and slowly returns to the lavas screen pipe by hand to ensure that it cannot be pulled. At this time, the suspension device is completely fixed and firm, and then the drill pipe is withdrawn to ensure that the gas screen pipe will not shake and rotate until the hole is sealed and the gas drainage pipe is connected.

In order to ensure the smooth progress of drilling and prevent drilling accidents caused by rock burst, drilling holding and hole collapse deformation, it is strictly prohibited to stop the drill pipe for a long time when it is in the hole. All materials shall be adequately placed on the rig site to prevent sticking during waiting.

When the drill pipe is withdrawn, it should be ensured that the withdrawal is not more than three drill pipes and the drilling rig is rotated for 1-3 minutes. Ensure the hole-forming of the hole and the smooth withdrawal of the drill pipe.

Drill pipe repeated use, should do a good job of cleaning and maintenance. The special thread grease for geological drill pipe distributed by our company can be evenly coated with a brush, which can effectively prevent the occurrence of thread damage and thread seizure, greatly reduce the unscrewing torque of the drill pipe, and multiply the service life of the drill pipe.

5.advantage and benefit analysis

At present, the large hole lower screen pipe products in the market are mixed, and the product quality is uneven, which brings great troubles to customers in selecting products. They are mainly limited to laying 36mm screen pipe under Φ73mm drill pipe and 50mm screen pipe under Φ89mm drill pipe. For mines with gas concentration exceeding the limit, hole collapse in soft coal seam and need to improve gas extraction efficiency, the above gas screen pipe cannot meet the requirements and is used in dry construction drilling, most of the spiral drill pipe is used, and there is also a lack of formed products for the process of laying the screen pipe of the spiral drill pipe. Our company has actively carried out research and development for the above drilling problems, and has formed a customized drilling scheme for laying the screen pipe with different diameters for different drill pipes. It can save construction cost and improve comprehensive construction efficiency for drilling construction of coal mine units.

Key words: