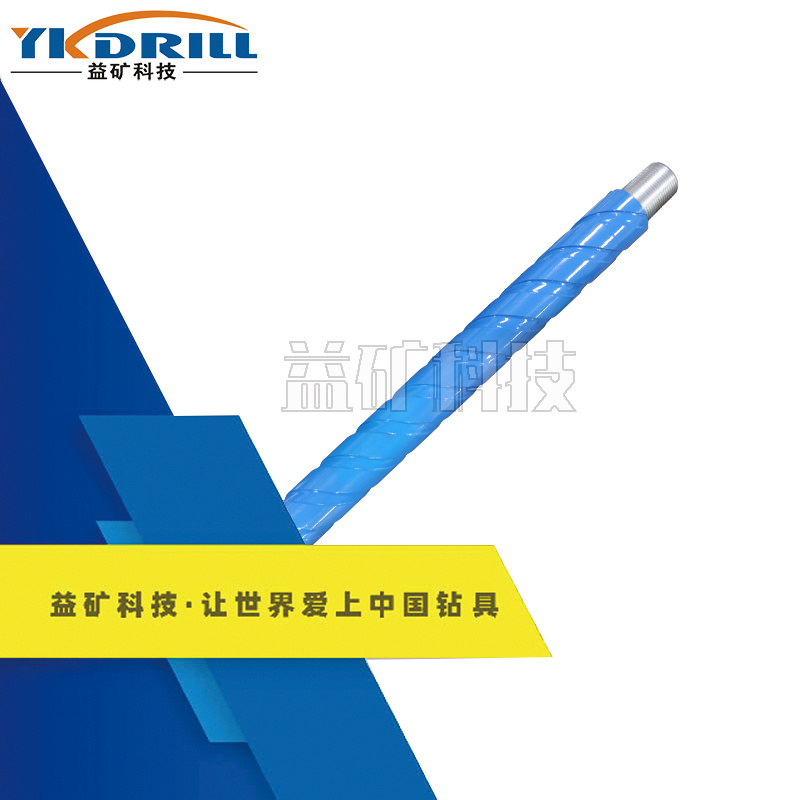

Large hole drill pipe gas drainage drill pipe beneficial mine technology

Release time:

2021-07-23

Author:

Source:

Configuration of integrated construction scheme for large hole drill pipe gas drainage drill pipe drilling and drainage: product name, diameter, unit quantity remarks large hole groove drill pipe Φ89mm root/meter 200 diamond open closed drill Φ120mm only 2 gas drainage screen Φ60mm 200 screen suspension Φ120mm only 2 rear water tail Φ89mm only 2 mine dust collector set 1 this scheme can be applied to existing hydraulic crawler drilling rigs of customers without additional purchase, air (water) cooling and dust reduction shall be adopted, and dust collection by drilling and pipe laying shall be carried out simultaneously. Operating instructions: 1. Diamond open and close drill bit and Chase

| |

Integrated drilling and pumping construction scheme

Scenario Configuration:

| Product Name |

Diameter | Unit | Quantity | Remarks |

| Large hole grooved drill pipe | Φ89mm | Root/meter | 200 | |

| Diamond Open Close Drill | Φ120mm | Only | 2 | |

| gas drainage screen | Φ60mm | Meters | 200 | |

| Screen suspension device | Φ120mm | Only | 2 | |

| Rear tail | Φ89mm | Only | 2 | |

| mine dust catcher | Sleeve | 1 |

The scheme can be applied to the customer's existing hydraulic crawler drilling rig, no additional purchase, the use of wind (water) cooling dust reduction, drilling pipe laying dust collection synchronization.

Operating instructions:

1. Diamond open and close drill bit and large hole drill pipe are connected to the drilling machine.

2. The rear tail is connected to the rear of the power head of the drilling rig.

3. Assemble the dust collector and install it at the opening for drilling.

4. Remove the rear water tail after drilling to a predetermined depth.

5. Withdraw the drill string and leave a fixed space for the top anchor suspension device.

6. Assemble top anchor suspension device and gas drainage screen.

7. Close the top anchor suspension device and push it into the large hole drill pipe.

8. Connect the gas screen pipe in turn to push the top anchor suspension device to the drill bit

9. Slowly push the top anchor suspension device to open the drill bit and close the beam.

10. The top anchor suspension device will automatically open the hook for fixing after the drill bit is completely pushed out.

11. Withdraw the drill until the rod withdrawal is completed.

12. Clean up the construction site for hole sealing and gas drainage pipeline access.

Note:

1. The drilling pressure of the drilling rig shall be kept within 6Mpa.

2. When the WOB increases, stop the propulsion operation, carry out rotary slag discharge, quickly reduce the water supply ratio, or carry out back drilling until the drilling rig pressure returns to normal value.

3. Timing of top anchorage, slowly return to the screen tube by hand to ensure that the top anchorage suspension device is completely hung on the coal wall.

4. Ensure that the gas screen will not shake and rotate when the drill pipe is withdrawn.

5, back drilling should ensure that the withdrawal is not more than 3 drill pipes for drilling rig rotation 1-3 minutes.

6, drill pipe use, should do a good job of cleaning and maintenance. The special thread grease for geological drill pipe distributed by our company can be evenly coated with a brush, which can effectively prevent the occurrence of thread damage and thread seizure, greatly reduce the unscrewing torque of the drill pipe, and multiply the service life of the drill pipe.

Warning!!!

In order to ensure the smooth construction of drilling operation and prevent drilling accidents such as rock burst, drilling holding, collapse and deformation of drilling holes, it is strictly prohibited to stop the drill pipe for a long time when it is in the hole! All materials shall be placed on the construction site to prevent sticking accidents during waiting.

Key words:

Drill pipe, carry, device, suspension, gas, screen, drilling machine, drill bit, drilling hole