PDC bit selection, how to choose the most cost-effective bit?

Release time:

2021-08-17

Author:

Source:

An important concept when choosing a drill bit is that regardless of the quality of the drill bit or drill bit, the economics of drilling should always be measured in terms of cost per foot. Engineers and salespeople should correctly choose the most economical drill bit per unit depth to reduce costs and obtain higher profits. In particular, the price of a PDC bit may be 20 times the price of a milling bit and four times the price of a tire bit. But in many cases, PDC bits are a more economical option because PDC bits usually have a faster drilling speed (ROP) or better durability (longer). Again, there are no absolute advantages or disadvantages to choosing a drill bit

An important concept when choosing a drill bit is that regardless of the quality of the drill bit or drill bit, the economics of drilling should always be measured in terms of cost per foot. Engineers and salespeople should correctly choose the most economical drill bit per unit depth to reduce costs and obtain higher profits.

In particular,PDC BitsThe price can be 20 times the price of a milling drill and four times the price of a tire drill. But in many cases, PDC bits are a more economical option because PDC bits usually have a faster drilling speed (ROP) or better durability (longer). Again, there are no absolute advantages or disadvantages to choosing a drill bit. All based on drilling costs per foot.

Whether it is a PDC drill, milling or insert cone drill, it must be an economically "reasonable performance" standard. "Reasonable performance" is sometimes achieved by reducing the speed, and sometimes simply staying in the hole for a longer time.

Therefore, break-even analysis is very important when we consider whether to use more expensive drill bits. That is, for a particular well, can we compensate for the additional cost of the drill bit in other ways.

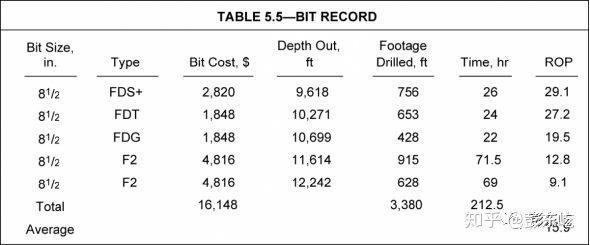

List of Smith Drill Parameters

Let's take the above eight-and-a-half inch Smith drill as an example for actual drilling. Starting from the first column, the size of the drill bit, the type of drill bit, the price of the drill bit, the depth of the well at the beginning, the depth of drilling, the operating market and the well speed. To facilitate the calculation, let's write down some key data and assume two variables, as follows:

Drilling time = 212.5 hours

Start time = 54.3 hours

Rig operating cost = $300/hour

Drill cost = $ 16,148

Total lens = 3,380 feet

Assumed starting speed of 1000 ft / h

The assumed spare PDC bit price is $18,300.

First, we can calculate the price of each well under current conditions.

C = 300 *(212.5 54.3) [16148] / 3380 = $28.46/ft

Second, since the new bit has two unknown variables (penetration rate and depth), we first assume that the new bit can reach 3,380 feet.

Breakeven point ROP = 300 / {28.46- [300*12,000/1000] 18300] / 3380} = 13.7ft / hr

That is, if the drill bit can hit a distance of 3,380 feet at a speed of 13.7 feet per hour, the break-even point of the new drilling plan can be reached.

In the third step, we can also assume that the drilling speed is 20ft / hr, then we can calculate the break-even point of the drilling depth

Break-even shot =(300*12 18300)/(28.46-)300/20=1627 feet

That is, if the drill bit can hit 1,627 feet at 20 feet per hour, the break-even point of the new drill bit solution can be reached.

Of course, in the actual drilling process, due to the existence of geological, artificial and various unexpected variables, the ideal situation in the calculation will not actually occur. However, the idea of calculating the economy of bit use has always played an important role in the bit selection process. This is the basic guiding idea of "how to maximize the benefits of drilling a well.

Key words: