Drill pipe drilling into piles, drill pipe length is not long enough to do

Release time:

2021-08-25

Author:

Source:

How to deal with the situation that the length of the drill pipe is less than the design length when the cast pile is drilled with the drill pipe? The problem encountered by this colleague is a bit serious. After testing bored piles in their project, they found that the length was not enough, some of them were 2 meters in length, and some of them were 4 or 5 meters in length. The types of bored piles are soil foundation, friction pile and single pile bearing capacity. To this end, we give the solution: Answer 1: test qualified? qualified, deduct and impose the construction unit unfinished construction project fine. If it is not qualified, please submit the detailed information (marked with short pile drawing, test is not qualified) to the design institute, and the design scheme will be issued.

Usedrill pipeWhen drilling and pouring piles, how to deal with the situation that the length of drill pipe is less than the design length?

The problem encountered by this colleague is a bit serious. After testing bored piles in their project, they found that the length was not enough, some of them were 2 meters in length, and some of them were 4 or 5 meters in length. The types of bored piles are soil foundation, friction pile and single pile bearing capacity.

To this end, we give the solution:

Answer 1: test qualified? qualified, deduct and impose the construction unit unfinished construction fines. If not qualified, please submit the details (marked with short pile drawing, test not qualified) to the design institute, and the design plan will issue a fill plan or other construction plan to strengthen the foundation.

Answer 2: Check the geological report and piling construction records to see if the pile end enters the bearing layer. If it enters the bearing layer, as long as the pile body quality prevails, the impact on the bearing will not be too great. After completion, the engineering pile can be used. If it does not enter the bearing layer, the vertical bearing capacity of a single pile shall be determined according to the static load test, the design unit shall reinforce the pile according to the difference between the vertical bearing capacity of the single pile and the design value.

The reinforcement method starts from two aspects: first, starting from the design load analysis, the upper load is checked. When the vertical bearing capacity of a single pile changes little, can we consider reducing the upper limit load to solve the problem? Second: Solve the problem of insufficient bearing capacity of the pile:

1. The simplest method is to repair piles, but the cost is relatively high;

2. When the difference is within 15%, the foundation soil can be considered to participate in the bearing capacity, that is, the composite foundation reinforcement method;

3. The pile bottom grouting method is more effective when the pile bottom is located in the plastic soft soil layer or the loose and slightly dense silted soil layer. The pile bottom grouting can improve the bearing capacity of the pile end and transfer the internal force of the pile bottom to the bearing layer.

4. Using pile side grouting method, when the pile body is long, it can strengthen the foundation soil within a certain range of pile body length and improve the friction force of the pile side soil body. The foundation soil around the cap shall be strengthened and accepted by static load test.

Answer 3: It is suggested to ask the design institute to check the calculation, which may not need to be processed, because the design safety factor obtained now is relatively large.

Answer four: cut corners. 1. The original pile length is more than enough, please calculate whether the current pile length meets the requirements. 2. Stack and set the bearing platform!

If the on-site bored piles do not meet the design requirements, the foundation should be strengthened. Beanwork summarize some ways to strengthen the foundation, as follows:

1. dynamic compaction

Dynamic compaction is a method of reinforcing the foundation by freely dropping a weight of several tens of tons from a height of several tens of meters. This is a new technology developed based on the heavy hammer ramming method.

First, field tests (lateral pressure test, horizontal plate test) are carried out at the construction site. In order to obtain a series of relevant data, according to the requirements of the original construction project, the penetration test, the determination of moisture content and the dynamic consolidation test in the laboratory were carried out in the undisturbed soil sample to obtain a series of relevant data. Optimal tamping time Optimal tamping energy, per point number, distance between tamping points, and provide evidence for the determination of the time interval between two times before and after hammering, h,M mainly depends on the depth of influence H. For various economic and technical reasons, there is a tendency to increase the descent distance h. The shape and size of the hammer should correspond to the type of topsoil, and now there are twelve different forms.

In general, for gravel packing, a hammer bottom area of 4 m3 is suitable, but for sediment, a hammer bottom area of at least 6 m3 is required. The principle of determining the number of ramming per point is that the volume of the soil is compressed to the maximum and the lateral movement of the soil is the smallest, usually 5-10 times. The tamping points are usually arranged in a square grid. The distance between the tamping points is determined according to the shape of the tamping pit and the increase in pore water pressure obtained from the test. This distance is typically 5 to 15 meters. The last one is continuous pounding, pounding energy is low. Before dynamic compaction was used, some projects were laid with a layer of sand and stone.

The world's largest hammer weighs 200 tons. It is carried by a special frame with 186 pneumatic wheels, and is hit once according to the specified grid point and the number of blows. The tamping pit is then filled with new or surrounding soil for the next tamping. The interval between the first pass and the second pass is usually 2-4 weeks, usually 2-4 days for clay or alluvial soil. If water is found to rise into the ramming pit, measures should be taken to drain the water, especially in cold weather, to prevent the formation of ice pits.

Two, rotary spray method

Rotary jet grouting is a new technology developed on the basis of ordinary chemical grouting.

The rotary jet method uses a high-pressure pump to jet the grout into the soil at high speed through the drill end of a special nozzle, and inject it in the grout nozzle. One side rotates slowly and the other side lifts slowly.

rotary spray method of construction procedures:

(1) The rig has been installed in place to test the jet performance.

(2) At the beginning of drilling, use low-pressure water spray to drill the drill pipe.

(3) After drilling, feed slurry with high pressure.

(4) Rotate the spray bar and lift it at the same time.

(5) After piling, put forward the drill pipe for low-pressure cleaning and cleaning the pipeline, move the machine to the place where the second pile needs to be rotated and sprayed, and then repeat the above steps.

A horizontal jet of high-pressure slurry continuously cuts through the soil and forces it to stir and mix. Finally, in the effective range of the jet force, a cylindrical solidified body composed of a continuous accumulation of disk-like mixtures is formed, which is called a rotating jet stack. The pile diameter is usually 0.5-1.0 m, with a maximum of 1.5m. The maximum pile length has reached 40 meters. Compared with the original soil, it has higher strength and smaller permeability coefficient, and can be used for foundation reinforcement and water interception. Generally, there are two ways to lift the drill rod upward during the rotating jet. One is the method of continuous lifting, that is, the drill pipe is continuously lifted upwards at a certain speed during the rotating injection until the entire pile is completed by the rotating injection. It is another stage lifting method, that is, three times on the continuous jet level and then a given spacing, the drill rod is rotated, and the spacing is still in the process of lifting the grouting, and the spacing is increased, and the three consecutive steps are injected in the new ground elevation After 3 times the interval, the entire pile is injected from the bottom to the top.

Three, grouting method

Grouting is a basic treatment method, the grouting is injected into the pores between the soil particles through the grouting pipe through the grouting pipe through the grouting equipment to reduce the permeability of the formation, enhance the strength of the formation, and consolidate the original loose soil particles into a whole., So as to prevent the formation deformation. The grout is injected into the formation by infiltration, filling and compaction. In short, the grouting method is to improve the physical and mechanical properties of the grouting object, and use the principle of air pressure, electrochemistry or water pressure to inject the curable grouting into the cracks and crevices of the medium.

High-pressure jet grouting method is a new type of foundation reinforcement method based on the application of grouting method and high-pressure jet technology. Compared with other basic treatment methods, it has the characteristics of wide application range, simple structure and good durability, and is considered to be one of the best basic treatment methods.

The mechanism of high-pressure jet grouting The method of high-pressure jet grouting is formed by spraying and mixing high-pressure water or slurry, and at the same time, it is injected into cement or composite slurry to form a new body, change the structure, replace the original stratum or all of them into a new composite structure, improve the bearing capacity or the anti-seepage ability of the original foundation, and achieve the purpose of foundation reinforcement and anti-seepage. The process is to use a drill or other drilling equipment to drill holes, and then lower the grouting pipe with a sprinkler to a predetermined soil depth, and use high-pressure water to spray the water from the nozzle. The pump or high-pressure mud pump has a high-pressure jet of 10 ~ 25Mpa to impact and destroy the soil at a predetermined depth. The jet energy is large and the speed is fast. When the pulsating flow pressure strength is greater than the soil strength, the soil particles are peeled off from the original soil, some small soil particles are discharged from the ground with the mud, and the remaining coarse soil particles are in the impact of the jet, Under the action of centrifugal force and gravity, it is then mixed into the cement slurry and mixed. If the size and quality of the grout are rearranged regularly, condensation will form in the soil. When spraying, if you lift one side and rotate one side, a cylinder will be formed, that is, a spray stack will be formed. If one side is lifted and the other side swings in a certain direction and angle, a wall will be formed. The high-pressure jet grouting construction equipment is mainly composed of high-pressure mud pump and drilling rig. Due to different injection methods, the type and number of machines and tools used in single-pipe, double-pipe and three-pipe rotary injection operations are different, mainly including drilling rigs, high-pressure pumps, mud pumps, air compressors, and special equipment for grouting. Drill pipe, grouting pipe, nozzle, high pressure rubber pipe, slag slurry pipe, flow meter, slag slurry mixer, etc.

Foundation Treatment and Reinforcement Mechanism of Cement-soil Mixing Method

Soil-cement mixing method is to use cement and other materials as a curing agent, through the field of special mixing machinery to mix the soft soil and curing agent, so that the soft soil hard into integrity, water stability and a certain degree of cement to enhance the strength of the soil, so as to improve the strength of the foundation soil and increase the modulus of deformation.

4. composite pile

Using industrial waste residue of fly ash as the main component and lime, sulfate (industrial mirabilite or phosphogypsum) as the basis, a new method was developed by using gravel pile, deep mixing pile and CFG pile compound pile on the basis of soft soil foundation reinforcement. Using industrial waste residue as the inspiration component, sand, gravel or other particles made from industrial waste residue as the aggregate of low-strength conical piles, the soft soil foundation is reinforced to form a composite foundation with high bearing capacity. Typically, the pile diameter is 15-25cm and the reinforcement depth is 8.0m. Use quincunx or square piles on a flat surface.

(1) The reinforcement mechanism of the composite pile is as follows: firstly, it is vibrated into a hole and compacted the foundation soil, then the composite material is added to vibrate the tube, the composite material of the pile body is vibrated, and further the soil between the pile bodies is vibrated. Pile, the pile machine moves and lowers the pile. Through the above effects, a composite foundation with composite piles as a solid is formed in the reinforcement area.

(2) The advantages of composite pile composite foundation are: small construction machinery and tools, fast construction speed, high installation accuracy, compared with other composite foundations, its construction technology is more reasonable. The moderate strength of the composite pile composite foundation can not only effectively improve the physical and mechanical properties of the soil between the piles, but also form an ideal pile-soil stress relationship, which can give full play to the bearing capacity of the soil between the piles.. The engineering cost of composite pile composite foundation is relatively low. Generally, the material price of CFG piles with the same volume and the same design strength is about 60% of that of CFG piles. In the case of the same composite foundation design bearing capacity, the total project cost is about 85% of the CFG pile.

5. lime pile

Lime pile refers to the suction column formed by drilling holes in the foundation and injecting quicklime to accelerate the consolidation of weak foundation.

After the mechanism is remolded, it will be stirred, and an appropriate amount of lime will be added to the soft soil at the same time. The lime will react with the soft clay minerals to form a water-insoluble complex, which will bind the soil particles together. The calcium silicate gel and the calcium silicate gel have the functions of packaging and connection, forming a network structure. The soil particles penetrate each other, and the contact with the soil particles is very firm, thus improving the physical and mechanical properties of the soil, it plays the role of lime reinforced curing agent. Specifically, the basic effect of lime on soft soil is as follows:

(1) By forcibly mixing quicklime and soft soil on the base layer, hydration occurs rapidly and Ca(OH)2 is formed. In the process of quicklime turning into hydrated lime, the heat generated promotes the evaporation of water, thereby reducing the water in the soft soil foundation. At the same time, the volume of lime expands, and the work completed by the expansion force is converted into the potential energy of the surrounding soil. For example, in the Yunfu Pyrite Line in Guangdong Province, there is a 4.5m covered cultural base treated by deep mixing with lime dusting. The drill bit diameter is 500ram. After the lime pile is formed, the diameter of the fine sand layer increases to 520mm and 600-700mm respectively within the diameter of the soft soil layer.

(2) Ca2 in hydrated lime reacts with soft soil particles through flocculation under the action of water, which makes the water film thickness of soft soil particles thin, reduces the plasticity of soil, increases the adhesion between soil particles, and improves the strength and stability of water soil. The above two chemical reaction processes mainly occur within a few hours after the strong mixing of quicklime and soft soil, which is the early basic effect of lime on soft soil.

(3) The active silica and aluminum minerals in the hydrated lime clay particles have a further slow chemical reaction. During this process, the water in the hydrated lime slurry is absorbed to form crystals, forming aluminate and calcium silicate hydrates, thereby changing the structure of diatomite. Clay. This reaction process will last for several years and is a follow-up action of lime on soft clay.

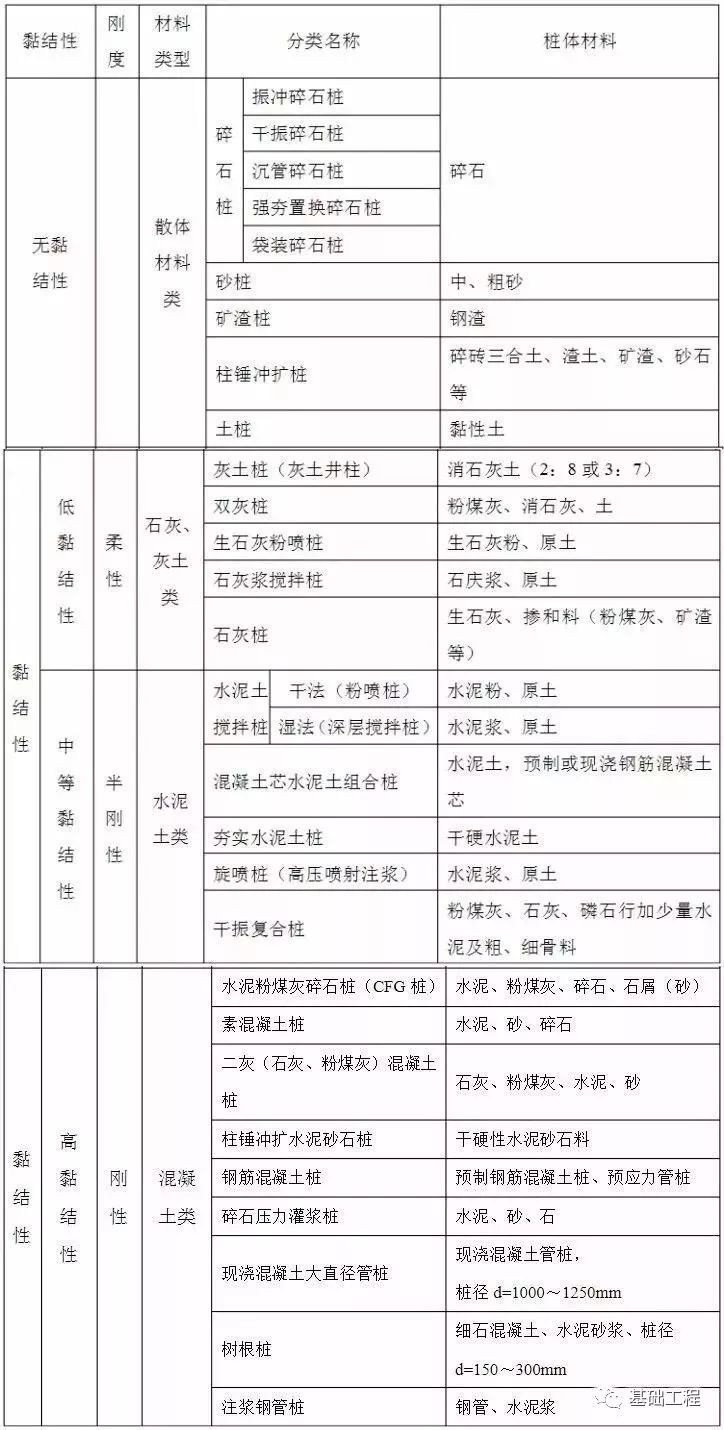

Classification according to the engineering characteristics of composite foundation reinforcement

Note: The stiffness and flexibility of the pile are relative and cannot be determined by the pile modulus alone. The stiffness and flexibility of piles are mainly related to the modulus ratio of pile to soil and the length-to-slenderness ratio of piles, which can be classified according to the relative stiffness of pile to soil. The relative stiffness of pile and soil can be calculated as follows:

I suggest that when K is greater than 1, it can be regarded as a rigid pile; when K is less than 1, it can be regarded as a flexible pile. There is no strict boundary between rigid piles and flexible piles in engineering.

Key words:

Drill pipe, soil, foundation, composite, method, reinforcement, grouting, formation, jet, lime