4. Screw drilling tool (hole bottom motor) The screw drilling tool is mainly driven by the screw drilling tool to rotate synchronously with the output shaft through the upper rotor to control the periodic change of the drilling fluid flow area, thus generating rotating torque, so as to realize the hole bottom drilling under the condition of high-speed rotation of the drill bit and improve the drilling speed. The tool can realize rapid drilling operation, effectively improve work efficiency, reduce construction cost, and has great application prospect. 5. Four-wing flat-bottom directional drill bit The four-wing flat-bottom directional drill bit produced by our company can be selected according to the actual drilling requirements of the formation, and can be integrally formed by tungsten carbide sintering. Also

4. Screw drilling tool (hole bottom motor)

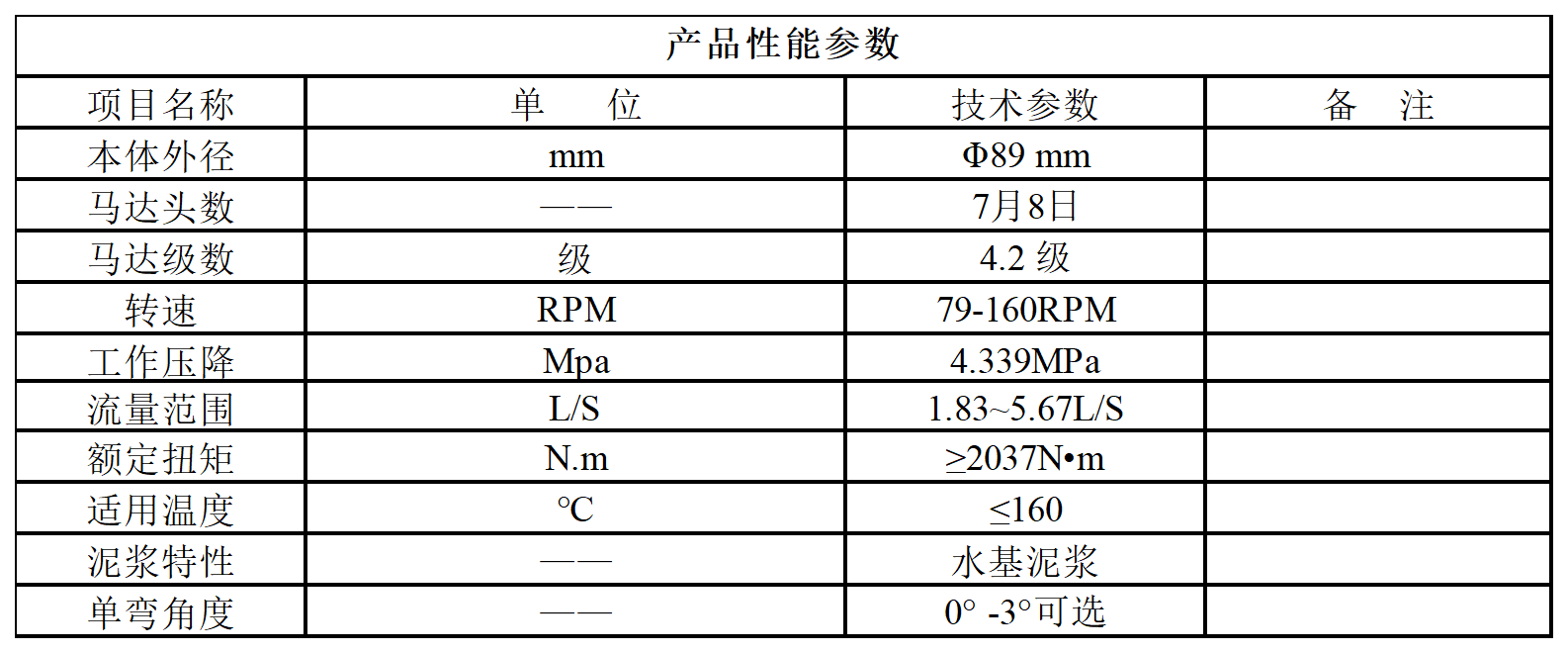

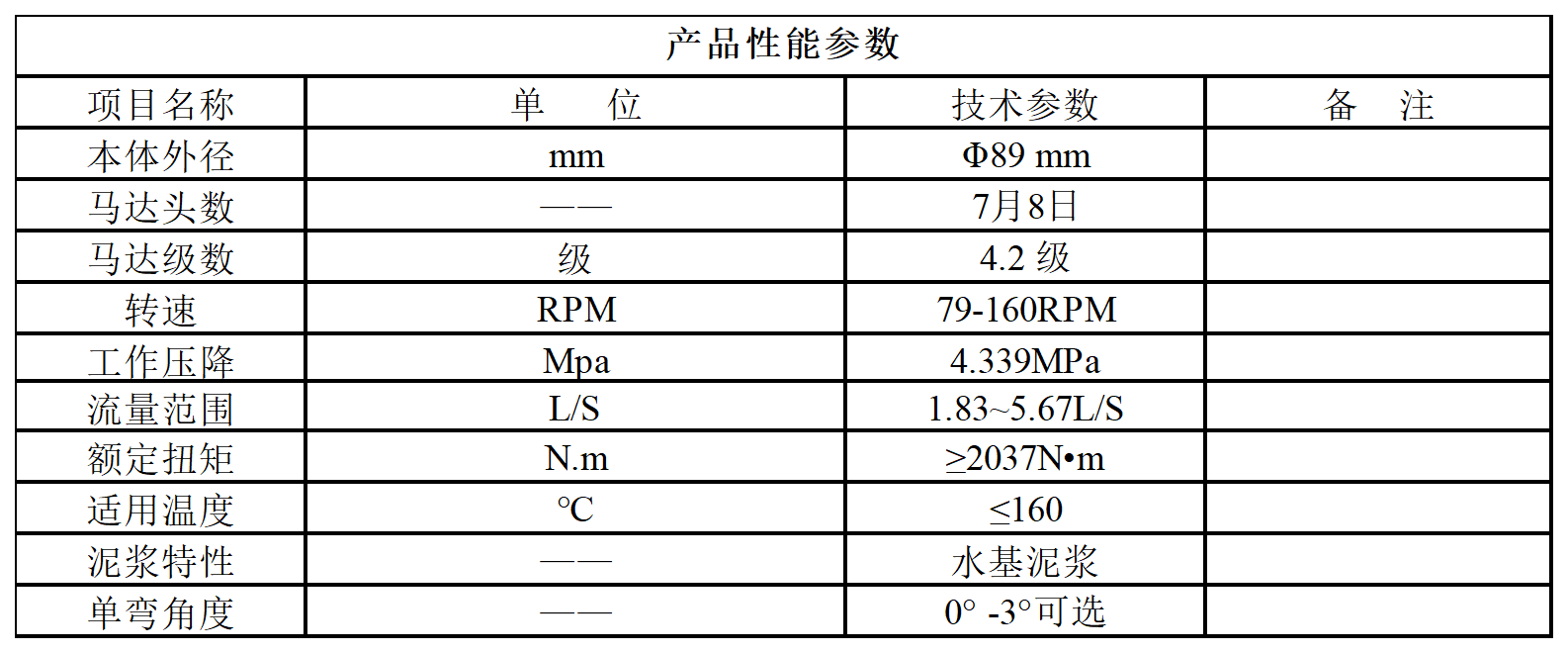

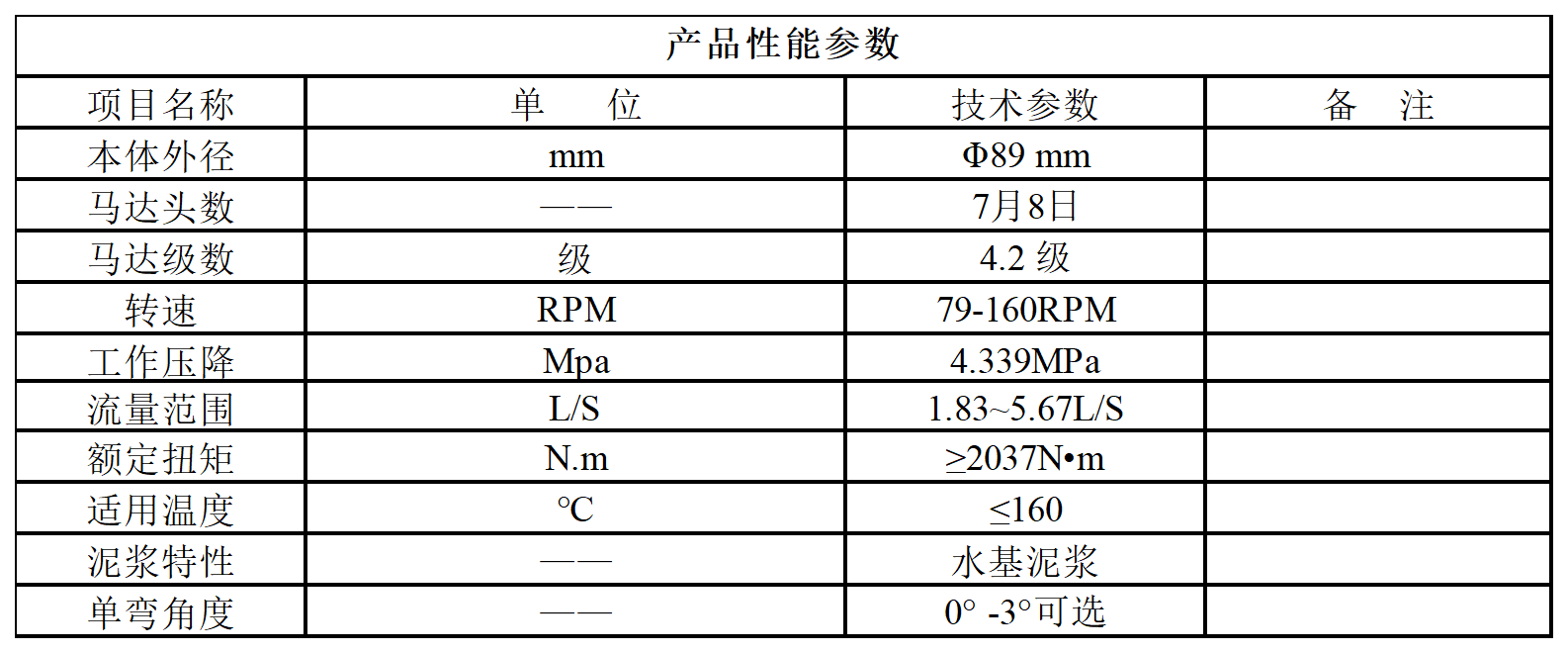

The screw drilling tool mainly uses the screw drilling tool to drive the output shaft to rotate synchronously through the upper rotor to control the periodic change of the drilling fluid flow area, thereby generating rotating torque, so as to realize the drilling at the bottom of the hole under the condition of high-speed rotation of the drill bit and improve the drilling speed.

The tool can realize rapid drilling operation, effectively improve work efficiency, reduce construction cost, and has great application prospect.

5. Four-wing flat-bottom directional drill bit

The four-wing flat-bottom directional drill produced by our company can choose various processing technologies according to the actual requirements of drilling strata. Tungsten carbide sintering can be used for integrated molding, and steel can also be used for forging molding. The crown is welded with multiple arranged composite teeth to meet the drilling requirements of strata with different hardness. High-strength hard alloy and sintered diamond particles are used on both sides of the blade to protect the outer diameter steel body, prevent bit scrap caused by excessive wear.

Product advantages

It can be used in most formations with f≤ 12 and can withstand the impact of drilling with a certain amplitude.

The composite sheet is processed with polycrystalline diamond particles with high wear ratio, and the service life of the composite sheet can be improved by 15 ° cutting edge.

Silver-based solder is used for welding processing to increase the welding strength and static shear strength of the composite sheet.

The carcass is processed by forging sintering and other processes to meet the needs of the use of mechanical properties to improve the density of the tissue.

The cumulative use footage can reach ≥ 60000m.

Drill, conduct, process, improve, adopt, compound, drill, drill, rotate, formation