Pier thick integrated B19 anchor cable drill pipe

Release time:

2022-03-01

Author:

Source:

Our company produces a series of products such as pneumatic drill drill rod, one-shaped finished brazing rod, cross-shaped finished brazing rod, etc. The rod body adopts 55SiMnMo and 90CrMo high-quality hexagonal hollow alloy steel as raw materials. The products are calcined under high pressure and heat treated by vacuum overall quenching and tempering. The application of CNC automation equipment processing molding, to ensure stable and reliable product quality. The tail of the air drill pipe is used with various hydraulic anchor drilling machines, and the head of the air drill pipe can be connected with various drill bits inside and outside. The drill rod of the pneumatic drill is divided into the bottom section anchor rod, the middle section anchor drill rod and the lower section anchor drill rod. The drill rods can be connected by a connecting sleeve, and the anchor drill rod connecting sleeve can be processed and produced according to the user's design requirements.

Our company produces a series of products such as pneumatic drill drill rod, one-shaped finished brazing rod, cross-shaped finished brazing rod, etc. The rod body adopts 55SiMnMo and 90CrMo high-quality hexagonal hollow alloy steel as raw materials. The products are calcined under high pressure and heat treated by vacuum overall quenching and tempering. The application of CNC automation equipment processing molding, to ensure stable and reliable product quality.

The tail of the air drill pipe is used with various hydraulic anchor drilling machines, and the head of the air drill pipe can be connected with various drill bits inside and outside.

The drill rod of the pneumatic drill is divided into the bottom section anchor rod, the middle section anchor drill rod and the lower section anchor drill rod. The drill rods can be connected by a connecting sleeve, and the anchor drill rod connecting sleeve can be processed and produced according to the user's design requirements.

Mine air drill pipe

Mine bolt drill pipe is based on the innovation and transformation of the wind drill pipe, is the replacement of the wind drill pipe products. It has the characteristics of wear-resistant, fast time-saving and labor-saving, and is more than a hundred times the life of the general air drill pipe, which is economical and practical.

Mine bolt drill pipe is a new type of product. It can detect gas and water. It can be used alone or in combination. It can use new drill bits and old drill bits to prevent drill bits from falling off. Light weight, rapid connection, is an essential advanced tool for coal mine water exploration.

Connecting the locator wind drill pipe

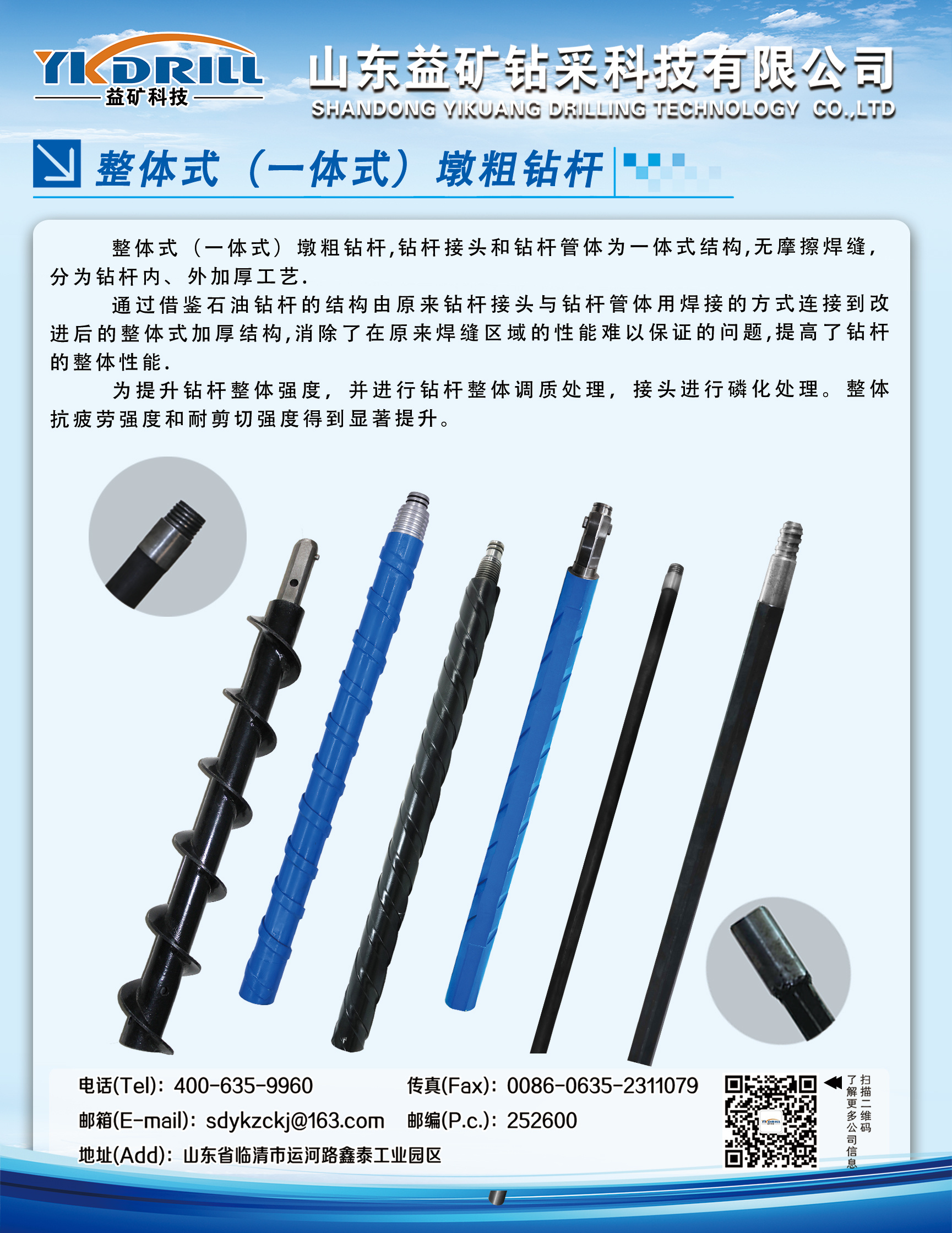

The drill pipe connecting the anchor cable of the positioner is 19mm in diameter and 1000mm in overall length. The thread form of the rod body is rectangular thread.

The connecting positioner anchor cable drill pipe adopts advanced high-pressure forging production process. The link form we adopt is male-female connection. The rod body adopts 55SiMnMo and 90CrMo high-quality hexagonal hollow alloy steel as raw materials. The product is forged under high pressure and heat treated by vacuum overall quenching and tempering.

Connecting the locator anchor cable drill pipe is processed and formed by CNC automation equipment to ensure stable and reliable product quality. This type of wind drill pipe is mainly suitable for mine roadway support drilling.

In order to correctly use the anchor rod and ensure the normal service life, the following points must be paid attention:

1. According to the test comparison or the product recommend of our factory, the correct selection of drill rod type.

2, should ensure that the drill rod and drill bit with good (taper consistent); If the drill rod taper is less than the drill bit taper, it is easy to break the tip.

3. For rock drilling holes with a depth of more than 2.0 meters, it is recommend to use a sleeve rod, that is, first use a short drill rod to open the hole, and then use a long drill rod to continue to extend the hole, so as to improve the service life of the drill rod (according to the hole depth, 2 sets of drill rods or 3 sets of drill rods can be used).

4, the hole should be stable, appropriate to reduce the air volume, to avoid the drill rod in the bending state of work, otherwise it will shorten the service life of the drill rod.

5. In the process of punching and withdrawing, try to avoid bending force of the drill rod to improve the service life of the drill rod.

6. The air volume of the rock drill should be adjusted according to the site conditions (rock conditions) to ensure the normal operation of the rock drill.

7. For the rock condition of the card, the cross-shaped bit shall be used.

8. The user shall not arbitrarily change the structure of the drill rod or use it after reprocessing, so as not to affect the normal service life of the drill rod.

9, when the normal use of ordinary drill rod is prone to batch early fracture, should be replaced with excellent drill rod; When the excellent drill is not in use, the large-size drill rod should be replaced or the wind pressure should be reduced.

10. The diameter of the drill rod should match the power of the rock drill. If the power is large, the drill rod of large size should be selected.

Key words:

Integrated, drill pipe, connection, adoption, service life, use, guarantee, normal, processing, positioner

Previous Page