New technology of beneficial mining technology-reverse circulation dust fixed-point sampling device

Release time:

2019-11-11

Author:

Source:

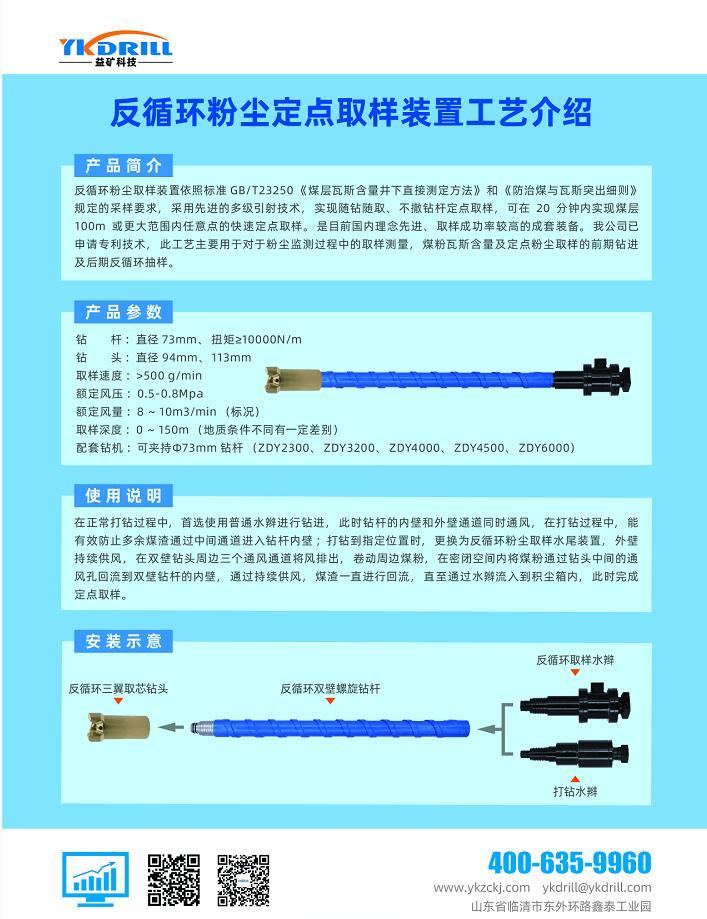

The reverse circulation dust fixed-point sampling device adopts advanced multi-stage ejection technology in accordance with the sampling requirements specified in GB/T23250 "Direct Determination Method of Coal Seam Gas Content Downhole" and "Detailed Rules for Prevention and Control of Coal and Gas Outburst" to realize fixed-point sampling while drilling without withdrawing drill pipe, and can realize fast fixed-point sampling at any point within 100m or more of the coal seam within 20 minutes. It is a complete set of equipment with advanced concept and high sampling success rate in China. Our company has applied for patent technology. This process is mainly used for sampling measurement in dust monitoring process, pre-drilling and post-reverse circulation sampling of coal powder gas content and fixed-point dust sampling.

Process Introduction of Reverse Circulation Dust Fixed-point Sampling Device

Reverse circulation dust fixed pointSampling device according to standardGB/T23250 "coal seam gas content underground direct measurement method"and 《Rules for Prevention and Control of Coal and Gas Outburst》The specified sampling requirements, the use of advanced multi-stage ejection technology, to achieve with the drilling, non-withdrawal drill pipe fixed-point sampling, can be in.20 minutes.Inner realization coal seam100Fast fixed-point sampling at any point within a range of m or greater. It is a complete set of equipment with advanced concept and high sampling success rate in China.Our company has applied for patent technology, this process is mainly used for dust monitoring in the process of sampling measurement, coal powder gas content and fixed-point dust sampling of pre-drilling and post-reverse circulation sampling..

Technical parameters:

drill pipe: diameter73mm, torque ≥ 10000N/m;

drill bits: diameter94mm,113mm;

Sampling speed:>500 g/min;

Rated working wind pressure:0.5-0.8Mpa;

Rated working air volume:8 ~ 10m 3/min (standard condition);

Rated sampling depth:0~150m (there are some differences in different geological conditions);

Requirements for supporting drilling rig: can be clampedΦ73mm drill pipe(ZDY2300、ZDY3200、ZDY4000、ZDY4500、ZDY6000)

Instructions for use:

In the normal drilling process, it is preferred to use ordinary water braid for drilling. At this time, the inner wall and outer wall channels of the drill pipe are ventilated at the same time. In the drilling process, it can effectively prevent excess cinder from entering the inner wall of the drill pipe through the middle channel. When drilling to the designated position, it is replaced with a reverse circulation dust sampling water tail device, and the outer wall is continuously supplied with air. The air is discharged through three ventilation channels around the double-wall around the drill bit, in the confined space, return the pulverized coal to the inner wall of the double-walled drill pipe through the ventilation hole in the middle of the drill bit. Through continuous air supply, the cinder will continue to flow back until it flows into the dust box through the water braid. At this time, the fixed-point sampling is completed.

shandong yi mining drilling technology co., ltd. production of drilling engineering dedicated to all kinds of geological drill pipe, spiral drill pipe, triangular drill pipe, coal drill pipe, drill bit, drill pipe, complete specifications! Strength manufacturers, trustworthy! company set research and development-production-sales-sales as one, welcome customers to purchase, tel: 0635-2311078

Key words: