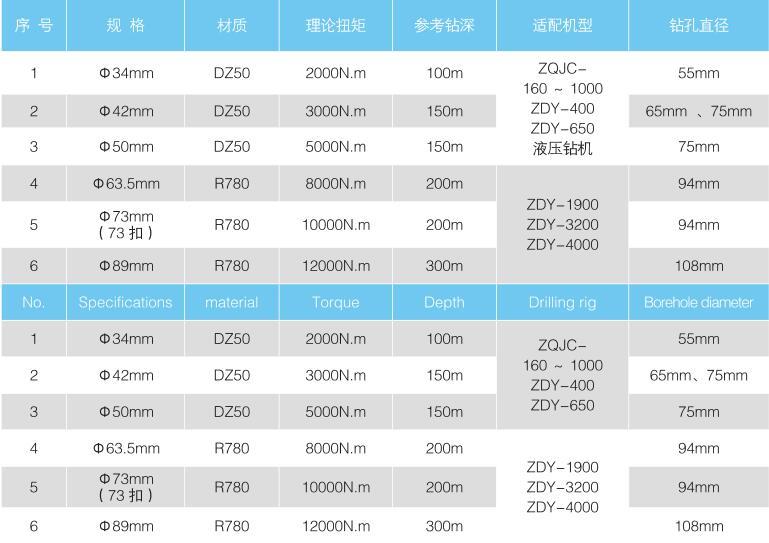

Definition of Special-shaped Multi-edge Groove Thrust Slagging Drill Pipe/Heavy-duty Three-edge Groove and Common Specification Parameter Table?

Release time:

2019-11-23

Author:

Source:

Definition, product advantages, uses and parameters of heavy triangular groove

Special-shaped multi-edge grooved thrust slagging drill pipe, referred to as heavy-duty triangular grooved drill pipe, is our company's new research and development of coal mine tunnel drilling book.

Coal seam gas drainage drill pipe, a new type of drilling tool product with a wide range of adaptability to coal seam hardness coefficient.

Department of our company's invention patent (hair

Ming patent number: ZL 200910064973.0), respectively, the production of external triangular transmission type grooved drill pipe, hexagonal double pin quick connection tensile

Type grooved drill pipe, large hole threaded connection type grooved drill pipe, hexagonal double pin quick connection tensile geological spiral drill pipe and other series of products.

Among them, the hexagonal double-pin quick-connection tensile type can perform the reverse function of the drilling tool and can withstand 350kN drawing force. in a reasonable bit diameter

Under the poor (10-15mm) design condition, the spiral groove thrust slag discharge structure is added on the basis of the triangular greasy smear stirring protection hole.

Selection of drill pipe joints and rod body materials by friction welding, machining center CNC machine tool finishing, with high torque, high resistance.

Grinding, adapt to the performance characteristics of high speed drilling.

Application areas:

It is widely used in deep hole drilling construction of high gas coal seam, especially soft coal seam.

The rotation of this series of drill pipes in loose cinder can cause vortex flow, and the coal powder deposited at the bottom of the borehole is raised by the edge of the drill pipe, and the coal powder in the hole is raised.

It is always in motion to avoid the accumulation and blockage of pulverized coal in the borehole; at the same time, the discontinuous spiral groove on the surface can assist the cinder to the outside.

Conveying, when the hole collapses in the hole, the hole collapses through the hole stripping function of the spiral groove. Therefore, it is not easy to cause the phenomenon of drilling and sticking.

The principle that the rotation of the special-shaped multi-edge cross-section rigid body in the loose coal slag causes the vortex flow along the axis of the rigid body, when the drill rod is buried by the loose drilling slag in the high-speed drilling,

A slag discharge channel (vortex zone) can be formed in several grooves around the drill pipe to allow the slag discharge air flow to pass through, and the air flow or water flow is fed through the inner hole,

The cinder is discharged through the slag discharge channel to reduce the rotation resistance of the drill pipe, and the phenomenon of drilling suction and sticking is not easy to occur. At the same time, there are discontinuous screws on the surface of the rod body.

The rotary groove can assist the coal cinder to be transported outward. When the hole collapses in the drilling hole, the collapsed hole is transported to the outside through the hole stripping function of the spiral groove.

Body round grooved drill pipe, rib drill pipe and special-shaped multi-edge grooved drill pipe all have cooling function, especially the latter has directional righting function (not easy to collapse holes,

Good hole quality), taking into account the principle of multiple slag discharge, will become the main drilling tool for gas extraction deep hole drilling.

Compared with the current coal mine gas drainage use

The smooth round drill pipe and ordinary triangular drill pipe are not suitable for hydraulic slag discharge drilling because the rod body has no groove structure and protrudes from the coal seam, especially the soft coal seam.

Dry drilling lacks cooling function under blockage (cinder cannot move along the axial direction).

Comprehensive comparison,Special-shaped multi-edge grooved drill pipe, with hole protection, pressure relief, strengthening, cooling four functions.

Parameter Table of Special-shaped Multi-edge Groove Thrust Slagging Drill Pipe

Key words: