Analysis of the reason for the fracture of the spiral drill pipe from the thread position

Release time:

2018-05-24

Author:

Source:

The drill pipe thread is a round tapered triangular thread processed according to MTT 521-2006 standard (its taper K = 1:16, 10 buttons per inch, and the tooth angle is 60). Drilling in the drill pipe thread to bear tension, compression, bending, torsion and their combined stress, and in the thread part of the stress concentration, therefore, more in the thread part of the fracture. When the threaded connection between the drill pipe and the receiver meets the requirements, because the section at the tail of the drill pipe thread is a sudden change section, the fracture is mostly at this point. In recent years, on-site drill pipe fracture often occurs in the middle of the thread near the 5th buckle of the small head of the cone, and accidents are more frequent,

The drill pipe thread is a round tapered triangular thread processed according to MTT 521-2006 standard (its taper K = 1:16, 10 buttons per inch, and the tooth angle is 60). Drilling in the drill pipe thread to bear tension, compression, bending, torsion and their combined stress, and in the thread part of the stress concentration, therefore, more in the thread part of the fracture. When the threaded connection between the drill pipe and the receiver meets the requirements, because the section at the tail of the drill pipe thread is a sudden change section, the fracture is mostly at this point. However, in recent years, on-site drill pipe fracture often occurs at the 5th buckle of the small head of the cone in the middle of the thread, and accidents are relatively frequent, causing less difficulty in drilling construction. Therefore, to explore the causes of this fracture phenomenon and its solutions, has become a subject that can not be ignored. This paper makes a preliminary discussion on this issue.

Analysis of 1. Drill Rod Fracture from Thread Position

From the force analysis and strength calculation of drill sweat, even if the drill pipe works under the maximum load, the strength of the thread part can meet the requirements. Then why does the drill pipe break from the 5th buckle of the small head? Only from the connection state of the drill pipe and the receiver to consider.The connection quality of drill pipe is related to its processing quality. The processing quality of drill pipe thread includes two aspects: cone accuracy and tooth shape accuracy. Among them, the tooth shape error mainly affects the service life of the thread and does not cause the drill pipe to break, while the cone accuracy directly affects the post-volume of the drill pipe.

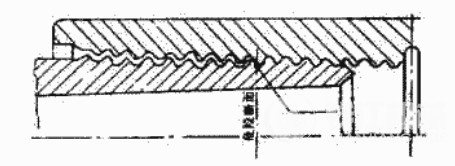

1. The thread taper of the drill pipe is less than the thread taper of the receiver. Only a few buckles at the end of the drill pipe are closely matched, while the clearance of other threads is increased in turn (Figure 1).

Fig. 1 Connection supporting state of drill pipe with thread taper less than receiver taper

The calculation shows that when the taper error between the drill pipe and the receiver is 20“At 34 ", the fit at the 5th buckle of the drill pipe meets the requirements, and the gap at the tail of the thread reaches about 0.3mm. If the taper error between the drill pipe and the receiver is 30, the tail clearance is 0.4mm, and the fit at the 8th buckle of the drill pipe meets the requirements. In other words, the greater the taper error, the fewer the number of thread turns of the tight connection. Since the tightly connected threaded part transmits the working load during work, and the tightest buckle bears the largest load, and the cross-sectional area here is much smaller than the tail of the drill pipe thread, therefore, the fracture is likely to occur at the tightest thread (e. g., section 5 when the taper error is 20 "24"). Through strength calculation, it can be seen that when the hole depth is 1000m and the drill string bears the maximum working load, the composite stress at the 5th thread of the drill pipe exceeds the allowable stress of the drill pipe (ΔRe <【Δ]]), that is, the strength of the pipe body there can no longer meet the requirements.

2. The taper of drill pipe thread is larger than that of receiving thread

In this case, the threaded tail of the drill rod is tightly threaded to the receiver end, and the thread gap of the drill rod head is large (Figure 2).

Fig. 2: Connection state where the taper of the drill pipe thread is greater than that of the receiver

At this time, the dangerous section is close to the tail of the drill pipe thread. Due to the large cross-sectional area of the thread tail, it is not easy to break under normal circumstances, and only the thread deformation and fatigue damage will occur under the action of alternating stress, which will cause the connection to fail. This is not discussed in this paper.

Influence of 2. Processing Technology on Connection Quality of Drill Pipe

As mentioned earlier, the quality of thread processing is an important cause of drill pipe breakage. The quality of drill pipe processing depends on the processing technology. At present, the drill pipe thread processing is carried out on the ordinary lathe or the pipe lathe. The processing process is divided into two steps: cone processing and burning pattern processing. The following from the two steps of the processing technology analysis of its impact on the quality.

1.Cone machining

The processing of cones on ordinary lathes is generally carried out by pulling a small drag plate. There are also models that are used, and on pipe lathes, the method of pulling against the template is used. A common problem with these two methods is that the cone angle accuracy of the workpiece depends on the accuracy of the small drag plate or the template. Since only the taper value is marked on the current machining drawing, no

The cone angle shall be marked, and the cone angle value shall be calculated by the operator. The calculation error may affect the cone angle accuracy. In addition, the large, medium and small carriage of the machine tool and the shaking of the template, the deformation of the processing tool, but also affect the cone angle accuracy of the workpiece.

2. Thread processing

At present, the thread of drill pipe is generally processed by manual knife driving method, and some of them are processed by profiling in good conditions. With the mold processing, as long as the mold pulling angle meets the requirements, it is generally possible to process qualified tapered threads. However, the manual tool driving rule requires the operator to continuously and evenly feed the tool with the movement of the lathe carriage. The amount of feed per revolution of the workpiece and.

The relationship between the movement of the large carriage shall meet the relationship X = tga · S, in the formula: X-feed (one revolution of the workpiece);

α-cone angle!

S-moving distance of the large carriage (one revolution of the workpiece).

In fact, even the most skilled skilled workers, it is difficult to meet this requirement. In this case, the tapered thread processed by this method not only has inconsistent thread height, but also often destroys the quality of the cone. The common cones are concave (Figure 3), and a few are convex. The concave tapered thread must only carry the head a few buckles when connecting, soIt breaks easily.

Fig. 3 Cone SurfaceConcaveTapered thread

3Inspection method

The exploration department processes drill pipe threads, and many of them use their own samples for inspection. Its requirement is that after the sample and the drill pipe are tightened, the end face of the sample should keep a distance of 6.5mm from the end of the drill pipe thread (I .e. 2.5 buckles). Obviously, this inspection method can only check whether the drill pipe and the receiver can be tightened, and cannot check the taper and tooth shape accuracy of the thread. With this means of inspection inspection will not guarantee the quality of products, it will make many taper, tooth shape unqualified products as qualified products into production, so that drill pipe broken accidents increased.

3. Suggestions on Improving Processing Quality

1Processing technology

a. The use of taper profile processing drill pipe thread, the processing method of manual knife.

B. Before turning the thread, use a standard taper light

The gauge shall inspect the conical surface. After the thread is processed, the thread shall be inspected with a quasi-thread gauge to strictly control the processing quality of each process.

2Product inspection

a.The requirements of MTT 521-2006 (on behalf of the national standard) shall be strictly followed during the inspection.

B. In the inspection, the taper quality shall be combined with the first inspection and the sampling inspection during the inspection.

c. After each inspection of 100 products, the accuracy of the inspection gauge (light gauge and wire gauge) shall be verified.

The fracture of drill pipe from the thread part is a very complex problem, and the reasons for this phenomenon are various. This paper only analyzes the causes of drill pipe fracture from the state of drill pipe taper, so as to improve the processing method and improve the processing quality,Reduce drilling accidents.

Key words:

Beneficial Mining Technology