Application of compressed air slag discharge cooling drill bit-Yikuang Science and Technology

Release time:

2020-06-09

Author:

Source:

At present, in the drilling of coal mine gas drainage construction, due to the geological conditions and technological requirements of the coal mine, water or air injection is injected during the drilling process to achieve the purpose of cooling the drill bit, so as to prevent the high temperature caused by high-speed rotation friction from causing the composite sheet to wear and fall off. During the implementation of water injection drilling, due to the change of water volume and the different softness of formation rocks, holes are often blocked due to the development and expansion of rocks exposed to water. Moreover, when water injection drilling is carried out at negative angle and vertical drilling, drill sticking is often caused by poor anti-slag effect. When drilling is stopped midway, drill pipes are locked due to rock cuttings solidifying in water. Therefore, water injection drilling is not suitable for compound in many cases.

At present, in the drilling of coal mine gas drainage construction, due to the geological conditions and technological requirements of the coal mine, water or air injection is injected during the drilling process to achieve the purpose of cooling the drill bit, so as to prevent the high temperature caused by high-speed rotation friction from causing the composite sheet to wear and fall off.

In the implementation of water injection drilling, due to the change of water volume and the different softness of formation rocks, holes are often blocked due to the development and expansion of rocks exposed to water. In addition, when water injection drilling is carried out at negative angle and vertical drilling, drill sticking is often caused by poor anti-slag effect, and drill pipes are locked due to rock cuttings solidifying in water. Therefore, water injection drilling is not suitable for composite drill bits in many cases.

When drilling with ordinary wind pressure, the wind pressure is transmitted to the composite drill bit through the inner hole of the drill pipe. During the transmission, the loss of air volume due to the long sealing and conveying distance of the drill pipe cannot achieve effective cooling effect. Due to the large ventilation aperture and uneven air volume dispersion, good slag discharge effect cannot be achieved.

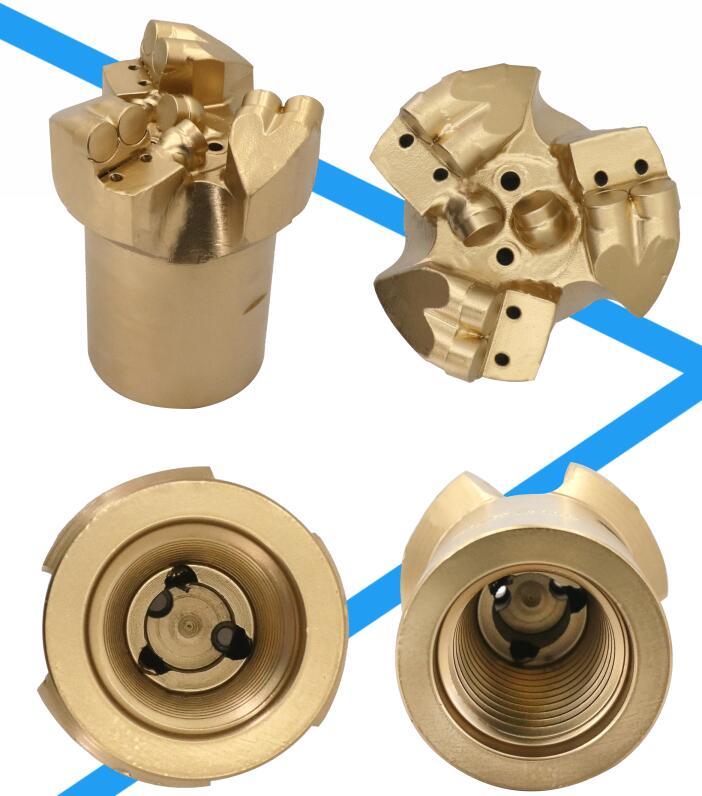

After long-term cooperation with the first-line users of coal mines, our company has developed a kind of compressed air slag discharge composite piece drill bit, which is characterized in that the lower end of the composite piece is provided with a compressed air outlet, the aperture of the air outlet is not more than 2mm, the included angle between the compressed air outlet and the composite piece is between, the high-pressure air forms a rapid jet wind in the 2mm nozzle hole, and then the direct-blown composite piece is arranged according to drill into the blade angle, thus achieving the purpose of rapid cooling.

Compressed air cooling slag discharge composite piece drill bit, its main structure is composed of crown structure main body, compressed air injection hole device and composite piece and other structures. The crown structure main body has a multi-body wing combination shape. The crown blade is arranged with composite piece. The lower end of the composite piece is provided with a compressed air outlet. The compressed air outlet performs air cooling on the composite piece through high pressure air to prevent burnout and abrasion caused by insufficient air volume and wind speed, through the high pressure air cooling can effectively solve the drill bit in the drilling fault caused by the sticking phenomenon and is 4-5 times of water cooling drilling.

The pressure air cooling slag discharge composite piece drill bit can effectively solve the high temperature burning phenomenon caused in the drilling process, and increase the slag discharge speed through high wind pressure drilling, effectively achieve the purpose of energy saving and consumption reduction.

Key words:

Technology, compound, drill, drill, cause, cool, pass, structure, reach, export.