Ordinary mechanized coal mining technology-coal cutting method of shearer

Release time:

2022-12-27

Author:

Source:

Ordinary mechanized coal mining technology-coal cutting method of shearer

Coal cutting mode of shearer

The reasonable coordination between shearer coal cutting and other processes is called shearer coal cutting method. Coal cutting side of shearer

Whether the type selection is reasonable or not is directly related to the yield and efficiency of the working face.

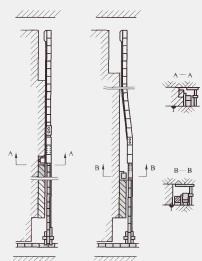

1. Two-way coal cutting, one knife back and forth

General mining of single drum shearer in medium and thick coal seam

The face uses this method of cutting coal. When the coal seam has a large dip angle

In order to compensate for the slippage of the conveyor, the conveyor is shifted.

The machine must start from the lower end of the working surface, so the lower

Line cutting top coal, random hanging beam, upward cutting bottom coal, cleaning

Process sequence of floating coal, push conveyor and pillar,

Upward cut bottom

as shown in Fig.

Cut the top in the downward direction, cut the bottom in the upward direction

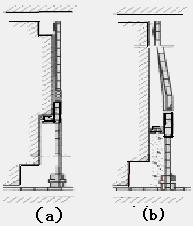

2. One-way coal cutting, one round trip

This coal cutting method is suitable for thin coal seams, drum diameter connection.

Near mining height, stable roof, sticky coal seam

Conditions such as strong roof property and failure of roof coal to collapse in time after coal cutting.

Shearer cuts upward from the lower (or upper) of the working face (or

Lower) Cut coal along the bottom, randomly clean the top coal and hanging beam, if necessary

Temporary pillars can be made; after the shearer cuts the upper (or lower) cut,

Turn over the arc-shaped coal baffle plate, quickly lower (or upper) coal loading and cleaning

The lost bottom coal of the machine lane, and randomly move the conveyor, support

Single strut, up to the lower (or upper) cut of the working surface, as shown in Fig.

shown in

Cut the top and cut the bottom

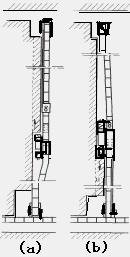

3. Two-way coal cutting, two-way cutting

This kind of coal cutting method is also called shuttle coal cutting. Figure 4-10

First, the shearer cuts coal from the bottom along the bottom of the cut,

Random hanging beam and push conveyor, and shovel and load floating coal at the same time,

Pillar support; after the shearer cuts to the upper cut, flip the arc.

Shaped coal plate, downward, repeat the same process.

Cut up and down twice

4.

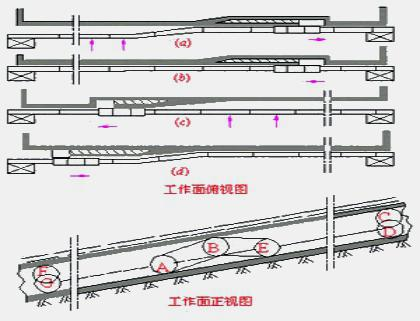

"∞"-shaped two-way cutting coal back and forth

As shown in Figure 4-11, in

Conveyor in the middle of working face

Set bending section, shearer from

The middle part of the working face is pulled up.

Lead, the roller gradually rises,

The coal cutting trajectory is A- B- C,

as shown in Figure 4-1. coal mining

After the machine cut to the upper lane,

Change the coal cutting track of the drum

C- D-E-A, while

The whole working face conveyor moves straight,

As shown in Figure 4-11b. In the state of Figure 4-11c, the coal cutting trajectory of the drum is

A- E-B-F, the upper end of the working face starts to move the conveyor; In Figure 4-11d

state, the coal cutting trajectory of the drum is F-G-A, the coal wall of the whole working face is cut straight,

However, the conveyor trough has a curved section in the middle of the working face, returning to the figure.

4-11a state.

This coal cutting method can overcome the roof control without a column at one end of the working face.

Disadvantages such as excessive time, uneven workload of workers, and the coal cutting process.

In the shearer self-feed, there is no need to arrange additional feed time, in the medium thickness

Coal seam single drum shearer is often used in general mining face.

Key words: