Ordinary mechanized coal mining technology-the feed side of the single-drum shearer.

Release time:

2022-12-27

Author:

Source:

Ordinary mechanized coal mining technology-the feed side of the single-drum shearer.

1. Push directly into the knife as shown in the figure.

a-before entering the nest; B- after entering the nest

Figure Shearer Straight

Into the cut

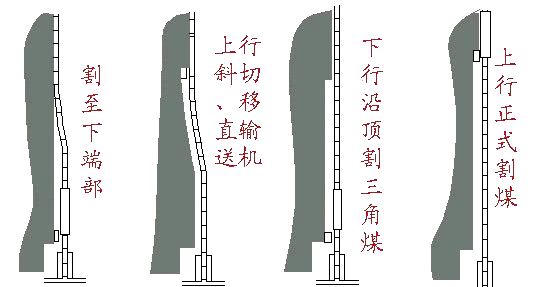

2. Oblique cutting knife

(1) Cutting triangle coal feed mode,

as shown in Fig.

Now mining

Coal machine upward cutting top coal, downward cutting

The coal cutting method of bottom coal is taken as an example.

The feeding process of triangular coal is as follows: ① Shearer cutting bottom

Coal to the lower end of the working face;

Run along the curved section of the conveyor until it is fully entered.

Into the conveyor straight section; when the roller along the top plate inclined

When the cutting into the coal wall reaches the specified cutting depth, it will stop.

Stop running; ③ push the conveyor head and bending section to make it in a straight line; ④ shearer returns to cut along the roof.

Triangle coal up to the lower end of the working face; ⑤ After the shearer has finished feeding, the coal is officially cut upward, and at the beginning, the drum is along

When the bottom plate is cut to the end point of oblique cutting, it is changed to coal cutting along the top plate by roller. This way of entering the knife is conducive

Face end management, conveyor to maintain a straight line, but more time-consuming, shearer at the end of the face

One round trip within 20~25m, and wait for the head to be moved and the end support to be supported again.

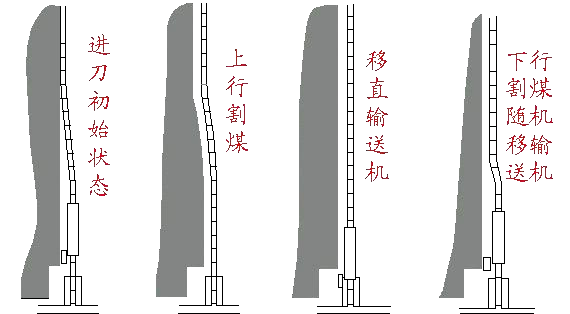

(2) Leave triangular coal feed mode, as shown in the figure.

The process of leaving triangular coal feed is as follows: ① After the shearer cuts coal to the lower end of the working face, it returns to the upward direction along the conveying.

The curved section of the conveyor cuts the triangular bottom coal (left by the upper knife), and when it is cut to the straight section of the conveyor, it is changed to cut the top coal until the cutting on the working surface; ② push the head and the curved section, move the conveyor straight, and leave it at the lower end of the working surface.

Triangle coal; ③ The shearer cuts bottom coal downward, and then changes to top coal at the triangle coal until the lower end of the working face; ④

Randomly push the transfer machine from top to bottom to the triangular coal at the lower end of the working face to complete the whole process of knife feeding.

Compared with the triangular coal cutting method, the shearer does not need to cut back and forth at the end of the working face,

The feeding process is simple, the moving head and the end support do not interfere with each other, but the coal wall at the end of the working face is not straight,

It is not easy to guarantee the quality of engineering specifications. Working Mode of Double Drum Shearer in General Mining Face and Double Drum Coal Mining in Fully Mechanized Mining

The machine works the same way.

(IV) coal loading and coal transportation

The coal loading of the general mining face is mainly based on the arc-shaped coal baffle installed behind the drum and the spiral blade of the drum.

The axial thrust generated in the process of rotation, the cut coal into the conveyor and transported out of the working face. For clear

The remaining coal can be transported by the shovel plate installed on the side of the coal wall of the conveyor.

Inside the machine. The general mining face where the coal is dropped by the coal planer, the inclined plow installed on both sides of the planer head is used to planer at the planer head.

The planed coal is loaded into the conveyor during the coal process.

The general mining face uses a flexible scraper conveyor to transport coal, and the overall movement of the conveyor depends on hydraulic pressure.

top to achieve. The installation spacing of hydraulic jacks is 5~6m. If coal shoveling plates are used in the middle tank, each

3m set one.

Key words:

Previous Page

Previous Page: