Crawler type full hydraulic variable diameter directional drilling rig for coal mine

Release time:

2023-12-11

Author:

Source:

Crawler type full hydraulic variable diameter directional drilling rig for coal mine ZYWL-6500DB coal mine with full hydraulic variable diameter crawler directional drilling rig is my company's latest research and development of a new general drill upgrade directional drilling rig. It is mainly used for the construction of coal mine gas drainage drilling, and can also be used for underground water exploration and drainage, geological structure and coal seam thickness detection, coal seam water injection, top (bottom) plate grouting and other high-precision medium and short-distance directional drilling within 350m. The drilling rig adopts a split structure and is mainly composed of drilling rig main machine, mud pump truck, measuring while drilling device, variable diameter grooving spiral drill pipe, etc.

for coal mineCrawlerFull hydraulicreducerdirectional drilling rig

ZYWL-6500DBFull hydraulic crawler type for coal minereducerdirectional drilling rigIs my company's new research and development of aNew general drill upgrade directional drilling rig. mainly usedCoal mine gas drainage drilling construction, can also be used for underground water exploration and drainage, geological structure and coal seam thickness detection, coal seam water injection, top(Bottom)Plate grouting and other types of high precisionShort and medium distance within 350mConstruction of directional drilling,The rigThe use of split structure, mainly by the drilling rig host, Mud pump car, Measurement while drilling device,reducerGroove spiral drill pipe and other components.

This drilling righasThe followingAdvantage:

- The drilling rig adopts advanced load sensing system, which can accurately control the feed pressure and rotation pressure, and has the characteristics of energy saving, high pressure control accuracy and overload protection;

- have a levelThe azimuth angle of 0~180 ° and the angle adjustment range of ± 90 ° meet the requirements of various construction angles and have a wide range of applications.

(3) The oil cylinder propulsion mechanism is adopted, which has long feeding stroke, stable propulsion and high transmission efficiency, and improves the ability of the drilling rig to deal with the accidents of holding and sticking in the hole;

(4) The chuck and the clamper are made of high pressure resistance and wear resistance rubber sleeve, and the material is imported polyurethane, which has long life, high reliability and low replacement rate.

(5) the selection of advanced large flow mud pump, small size, high pressure, stable flow, low noise, high reliability.

(6) Self-developed wireless measurement device with drilling, stable signal transmission, signal transmission in the form of electromagnetic waves, can use ordinary sealed drill pipe for drilling, reduce construction costs.

(7) The measurement while drilling device transmits parameters such as the inclination angle, azimuth angle, tool orientation angle, instrument temperature, battery voltage, etc. of the drill bit in the form of extremely low frequency electromagnetic waves, and at the same time can realize real-time display of the trajectory of drilling parameters, andCanTimelyAccording to the situationAdjust the direction of the elbow to achieve accurate directional drilling. The signal is automatically resolved during construction without manual intervention.

(8)Both the power head and the front gripper of the variable diameter directional drilling rig are equipped with the diameter difference between the adaptive joint and the rod body.20mm drill pipe passability, no more frequent replacement of slips during work, mechanical structure, large clamping force and other characteristics.

(9)reducergrooved spiral drill pipe:The structure of the whole rod joint is that the joint diameter is larger than the rod diameter, and the structural advantages: under the condition of fully ensuring the strength of the joint and the rod body, the flexibility of the whole rod is improved, which is beneficial to the bending of the drill rod in the hole to change the drilling trajectory..Such as diameter73 drill pipe, the joint size can be 89 in diameter, that is, it has the performance of 89 drill pipe, and the rod body has better bending than 89 drill pipe.

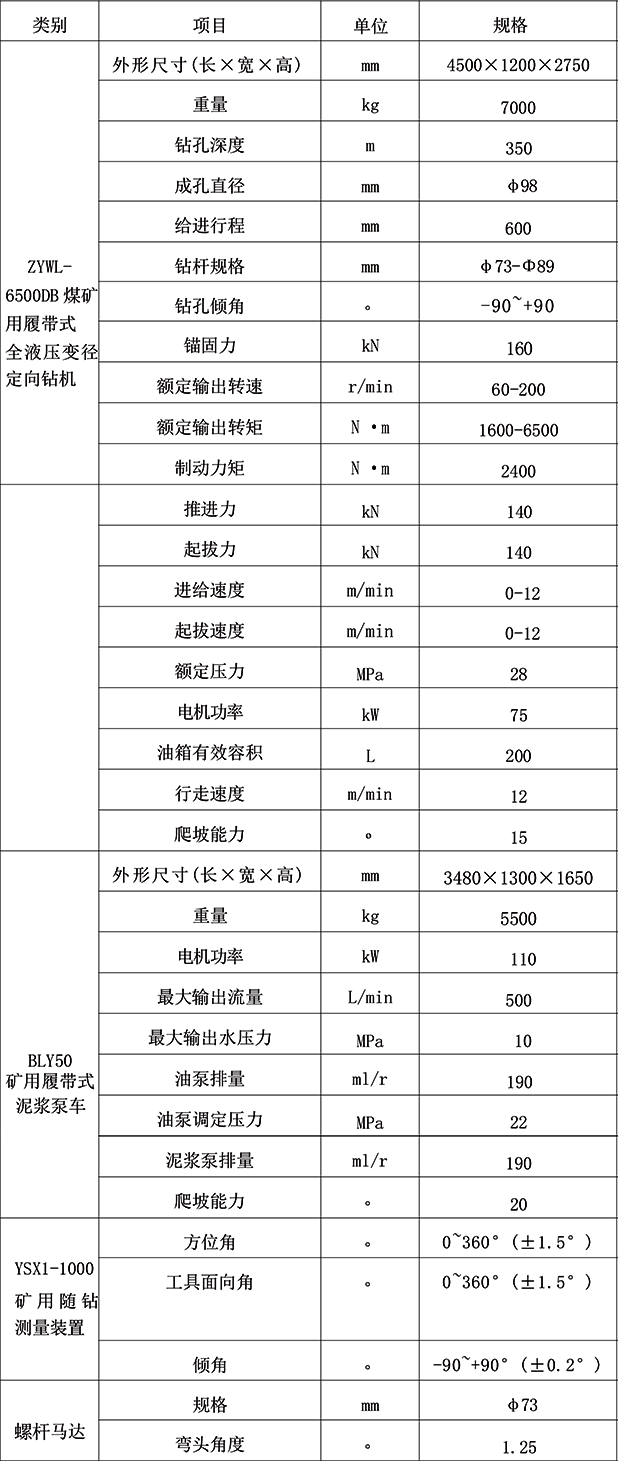

Rig parameters:

Key words:

Technology, drilling rig, drill pipe, orientation, joint, construction, structure, adoption, pressure, 89