Air drill is divided into several types? what are the specifications of models?

Release time:

2019-12-05

Author:

Source:

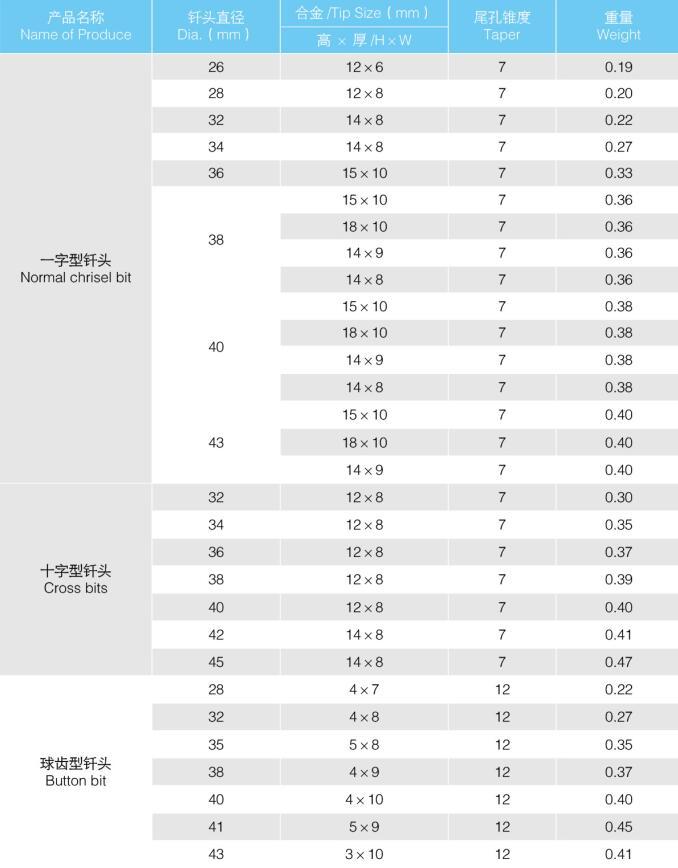

Wind drill is the main tool for impact rock drilling in mining engineering. Our company produces a series of products such as one-word, cross, three-edge, ball tooth type drill bit and drilling tools with tapered connection carbide drill bit.

wind bitIt is the main tool for impact rock drilling in mining engineering. Our company produces a series of products such as one-word, cross, three-edge, ball-tooth type drill bit, drilling tools, etc. The drill head body is made of alloy steel precision forging, and different alloy grades and product types are selected according to rock conditions, which are suitable for various grades of rocks.

ProductsType

Word drill bitIt is used for rock drilling and crushing, often with light internal combustion, electric, pneumatic and hydraulic [rock drill] and B22 drill pipe to drill rock holes with a diameter of less than 50mm in coal mine tunnels and other rocks. It is the main drill bit variety used in small and medium diameter rock hole drilling engineering in the mining industry.

Model: 40 word drill bit, 42 word drill bit.

A word drill bit is also called a word drill bit, mainly because the top of the drill bit is inlaid with a word-shaped carbide head. The flat-head drill body is made of 50cr steel by hot extrusion, which is made of cast steel. If the top cutter head is made of hard wear-resistant alloy screw thread, there are either with or without tap, and the drill pipe is directly stuck together without tap.

One-character drill specifications: φ28 φ32 φ34 φ36 φ38 φ40 φ42, of which 40 models are mostly used.

The word drill consists of a cutter rod, the cutter rod has a tip, and the tip has two cutting blades located on a main plane.

Use of a word bit: suitable for light rock drills, drilling holes with a diameter of 50mm or less, suitable for rock formations with low hardness. It is widely used in coal mine, iron ore, gold mine, copper mine, lead-zinc mine and other mines, railway, highway and water conservancy construction.

Word bit features:

The use of steel, alloy, high production efficiency.

☆ The manufacturing process is simple, easy to use, low price, and strong adaptability to rock mass performance.

☆ Drill bit that can ease the sudden change of drilling state in rock or coal seam, concrete, etc., so that the drilling operation is stable, and the drilling efficiency will not be reduced even when large chips are generated.

cross bitThe cutter head is designed to be cross-shaped, with four pieces of alloy named cross drill. The cross bit is mainly used for drilling holes, which can drill rock holes, coal holes, concrete holes, etc. Use with B22,B25 air drill pipe and [rock drill]. It is used for mining hard rock formations of 8-16 Platts hardness.

Specification of cross bit: Φ36, Φ38, Φ42, Φ45, Φ50, Φ60, Φ65

Cross bit use: suitable for high-power rock drill conditions, drilling fractured and other complex rock formations, strong radial wear resistance. Used in coalfield, tunnel, metallurgy, geology, water conservancy, construction, energy, chemical industry and mining, road construction, etc.

Cross bit features:

The use of mature technology, steel, alloy, high production efficiency, low cost. The cross bit will not break during drilling. It is conducive to saving auxiliary working hours, reducing the manual labor of workers and speeding up the project.

It has strong adaptability to rock drilling conditions and is almost not limited by the type of rock drill and rock mass performance, especially in hard and extremely hard high abrasive fracture developed rocks.

column tooth bitAlso known as the button bit, combined with the hydraulic rock drilling rig, is a modern rock drilling technology supporting.

The commonly used models of column tooth drill bits are [32 column tooth drill bits and 40 column tooth drill bits].

Taper connection drill tool post tooth drill bit 7 °, 11 °, 12 °"

The advantages of column tooth drill bit: long service life, accurate positioning, coarse rock cuttings, low dust, durability, no need for grinding, etc., compared with traditional sheet drill bit, fast drilling speed, long passivation service life of button tooth drill bit, its non-grinding life is about 5-6 times of the grinding life of the same diameter blade drill bit, which is conducive to saving auxiliary working hours, reducing labor and physical strength of workers and speeding up the project speed.

wind bitSpecification Sheet

Key words:

All have, drill bit, word, drill bit, cross, rock drilling, alloy, drilling, diameter, 40